Aussie nerd: That's awesome that your so interested in the project!

Brainator: Yep its all motor :)

Mamba: Just wait until I get the batteries,esc,receiver,and servo in there..its going to be very cramped

Overdriven: Since this is going to be a hardcore basher I think I'm going to try going with 100k in the center..sounds like this is usually what people suggest for bashing. Like you said it will take some testing.

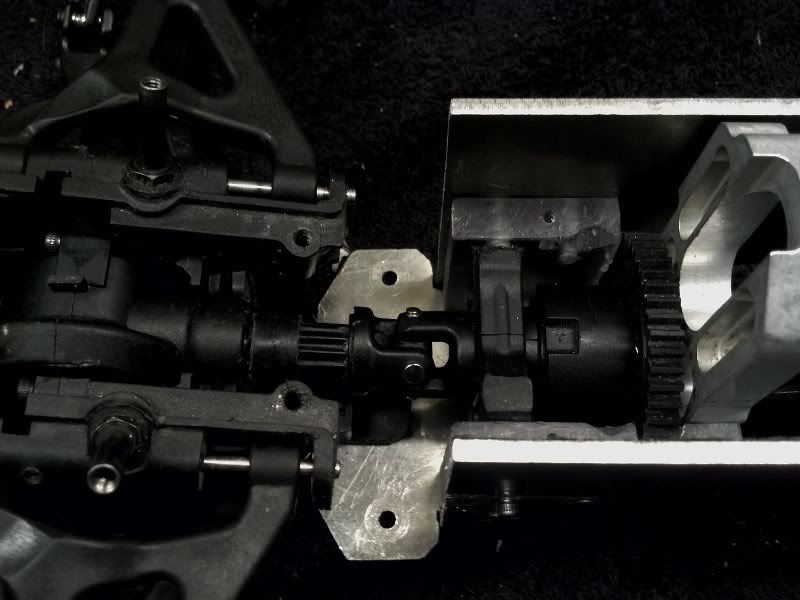

Tonight I got the drive-train all put together. I have decided to go with 100k diff oil in the center Since I had modified some Revo axles in my Evo8 project to fit in the Rc8 center diff I was able to use that..Some of you haven't seen my Evo8 project so I will describe the process of being able to use slider drive shafts for a 1/8th scale diff.

1.First I had to shave about 1/8th inch off of the black plastic part where the axle hooks on to the sliders.

2.Then I spent about an hour and half using my hand saw to cut down the axles so that they where the same length as the Rc8 inputs.

3. That's about all there is to it after that I just started putting it back together.

(Right is stock, Center is cut-down, Left is the completed one)

4. Once you have it put all together it should look like this.

Since I had that all done..all I had to do was measure to how much I needed to shorten the Revo drive shafts I recently had bought. It turns out that I didn't have to trim the drive shaft for the rear at all so that was easy as pie.

Now.. the front on the other hand was a bit more of a handful. I was planning on using just a cut-down slayer drive shaft for the front center drive shaft..but that ended up being way too long. The other problem is that on the Revo/Slayer/Summit the front differential is angled upward. My center diff is mounted horizontal. So I had to trim down the bulkhead so that the front differential could be at the correct angle to match up with the center diff.

I noticed that the male end of a Slayer drive shaft fits perfectly over the output shaft on the front diff. So I trimmed one down drilled a hole and put a pin thru it. To keep the pin in I made a simple sleeve. I have to say that so far this is the part that I'm the most proud of..because not being able to hook up a front center drive shaft is a big problem and I was able to fix it in a creative way..anyway enough talking..more pictures.

Tomorrow or friday a little package with my battery boxes and some drive shafts should arrive....that means I'll be able to get the driveshafts installed but more importantly...I will be able to get the batteries, esc,receiver,and servo mounted!!

But till then...back to my calculus homework.