|

Turnigy Trackstar 150A GenII ESC |

|

|

(#1)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

Turnigy Trackstar 150A GenII ESC -

10.21.2014, 02:22 PM

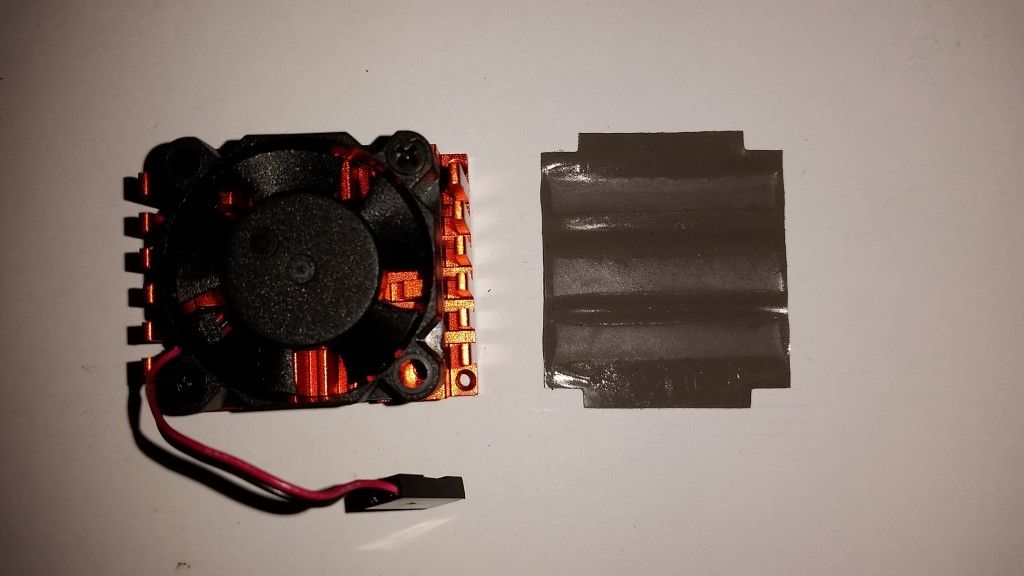

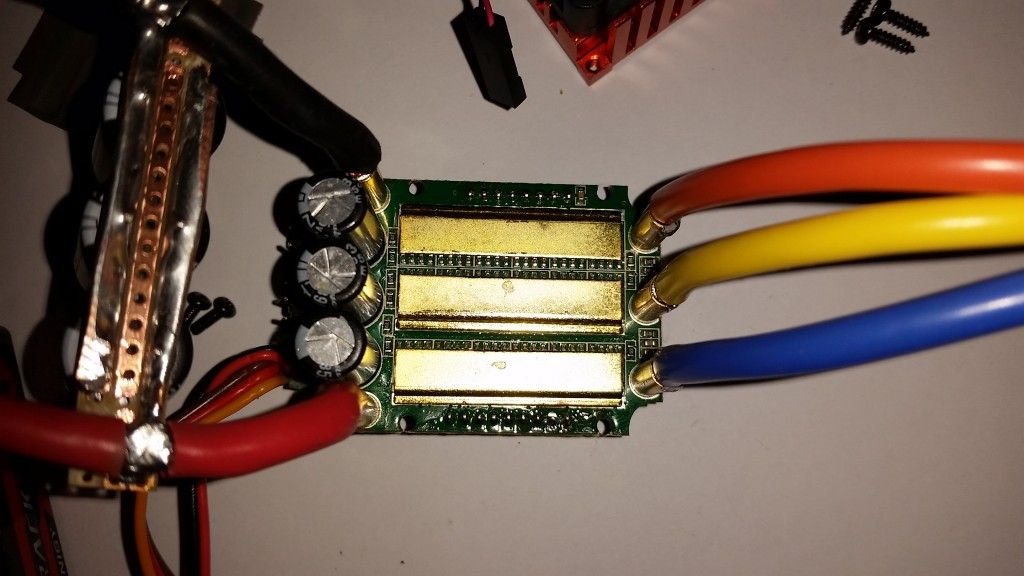

Wanted to share some pics and infos about the Turnigy Trackstar 150A Gen2 ESC I recently bought.

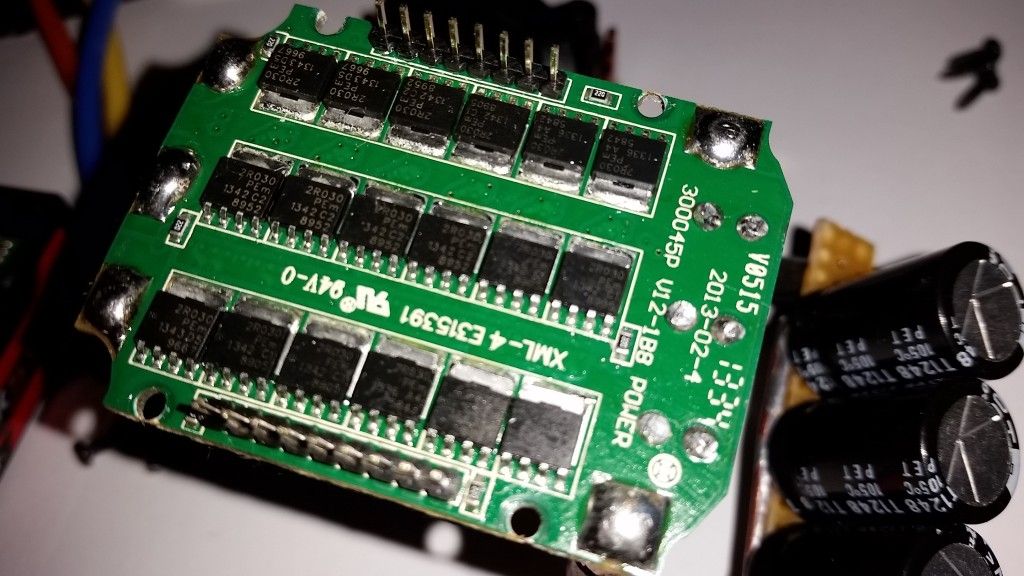

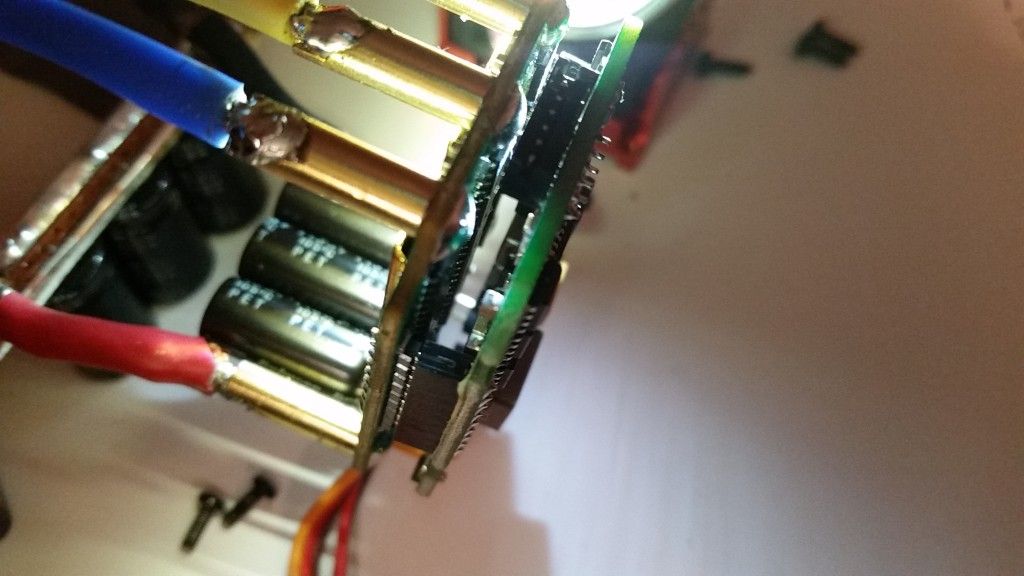

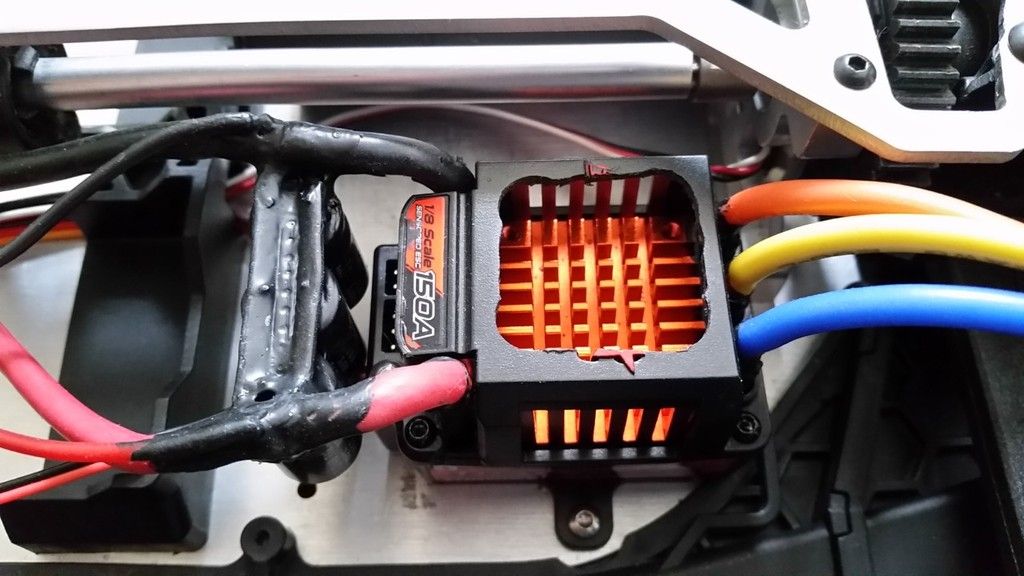

The plan is to run the ESC in my XO-1 powering the Turnigy XK5682-900KV motor. Generally, the ESC seems to be okay from a build quality perspective as far as I can see. What's not so nice is, that the two PCBs are not soldered to each other, they are using pin-connectors. Not sure if that matters only in theory, but I guess this could be a source for problems, especially with offroad usage. From a cooling perspective it's not too good IMHO. The FETs on the upper side have heatsinks that are soldered to the PCB, but there is air between the FET case and the heatsinks, so the heat has to travel through the PCB and then to the heatsinks. The lower FETs don't have any heatsinks at all, they rely on the PCB cooling path. On top of the heatsinks there is a thermally conductive pad which is needed to compensate for the difference in height of the heatsinks. On top of that, there is the orange heatsink. The heatsink is screwed on from the underside which causes the PCB to warp a little from the pressure. But that is actually a good thing if you want to improve cooling yourself, since everything can be removed. On Mamba Monsters for example, the Heatsink is glued to the FETs, impossible to remove. Here are some pics:

|

|

|

|

|

|

(#2)

|

|

|

RC-Monster Admin

Offline

Posts: 14,609

Join Date: Nov 2005

Location: Des Moines, IA

|

10.21.2014, 08:51 PM

From the looks of it, the bottom un-heatsunk PCB is the brains, so should generate little heat. I've seen lots of boards connected with pins like that, and as long as the case holds them together, there should be little concern even for off-road use.

And about the dual heatsink thing: FET packages are relatively poor at transferring heat, which is why they soldered the heatspreader to the PCB - which will pull heat from the FET faster than any HS on a plastic FET case. Then, they use the main large heatsink to dissipate the heat pulled from the heatspreaders. And even though the FETs on the underside of the PCB are not directly heatsinked, the large traces should be more than sufficient to transfer the heat upwards. IMO, not a bad design to be honest. A better option to me would be to use FETs that have a low rdson and a high slew rate - those two factors alone can result in less heat to be generated in the first place. Those FETs have an rdson of ~3mohm and a rise/fall time of ~50ns. Not sure how those figures compare with FETs of other current generation ESCs, but that's something to look at. |

|

|

|

(#3)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 235

Join Date: Nov 2012

Location: The Netherlands.

|

10.23.2014, 04:07 AM

The Tekin RX8 has the 2 boards also connected by a row of pins.

I never had a problem with that and I assume that Tekin has done it's homework? |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

10.24.2014, 07:14 AM

hi,

where did you get the cap bank? I think that its not a problem that the two layers are sticked together with pins, have seen that a couple of times. Manufacturer should be sky rc, isn't it? here some pics of mine, which has a different layout, dunno if the fets are the same http://www.rc-monster.com/forum/show...465#post428465 |

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.24.2014, 11:26 AM

Well, if that cooling design isn't bad at all, then I'm going to try it like it is :)

Not sure if it's really necessary to use lowest-resistance FETs, atleast Uber on rcgroups says it's not needed when ESCs are properly designed. It's just a few watts, if you have the cooling to remove the heat that doesn't matter I guess (?) Regarding the pin connection: Maybe it's just a theoretical problem, but I think it is a possible cause of failure when run offroad with lots of vibration, shocks and dirt. Those connectors are designed to be used in computers and other stuff that doesn't get abused in the dirt like RC cars do. The cap bank is selfmade from a piece of "Lochstreifenplatine" (not sure what that is in english, that kind of circuit board you can buy for making your own circuits). |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

05.18.2015, 04:45 AM

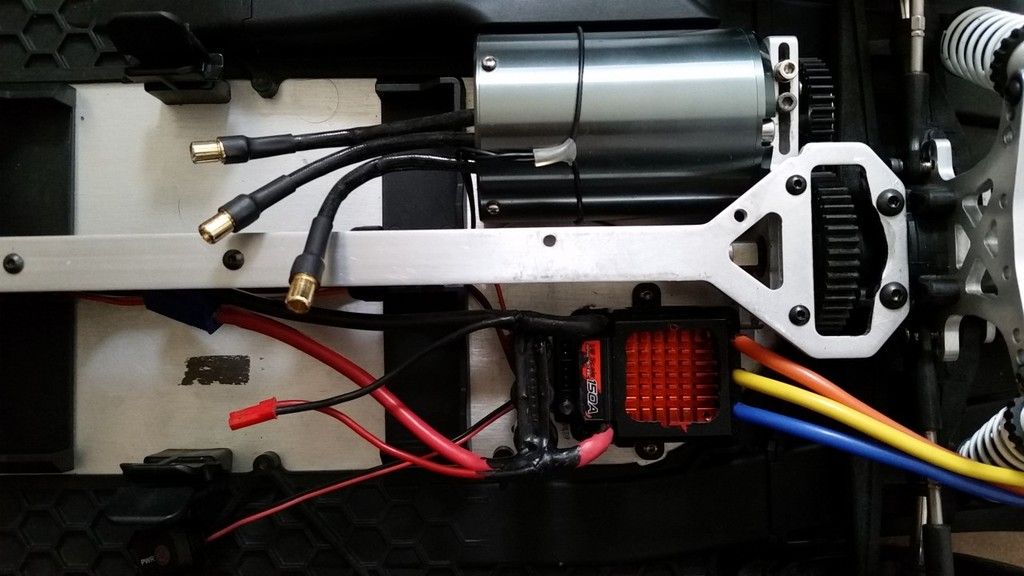

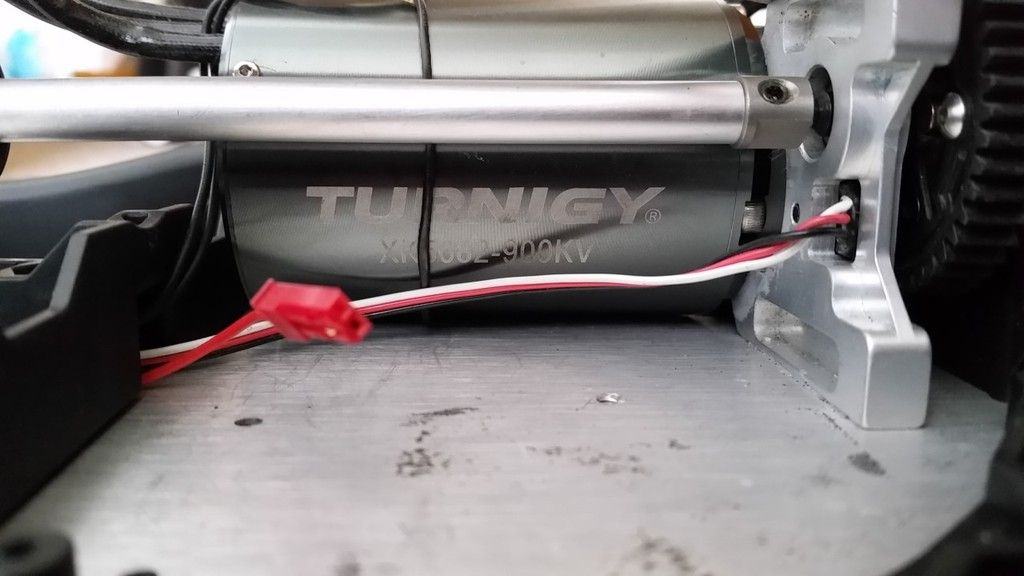

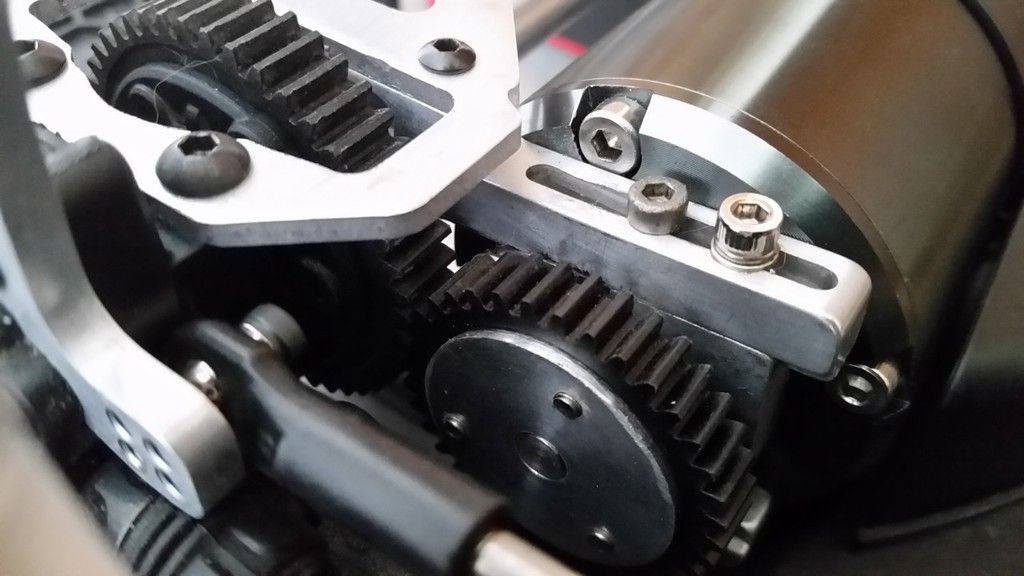

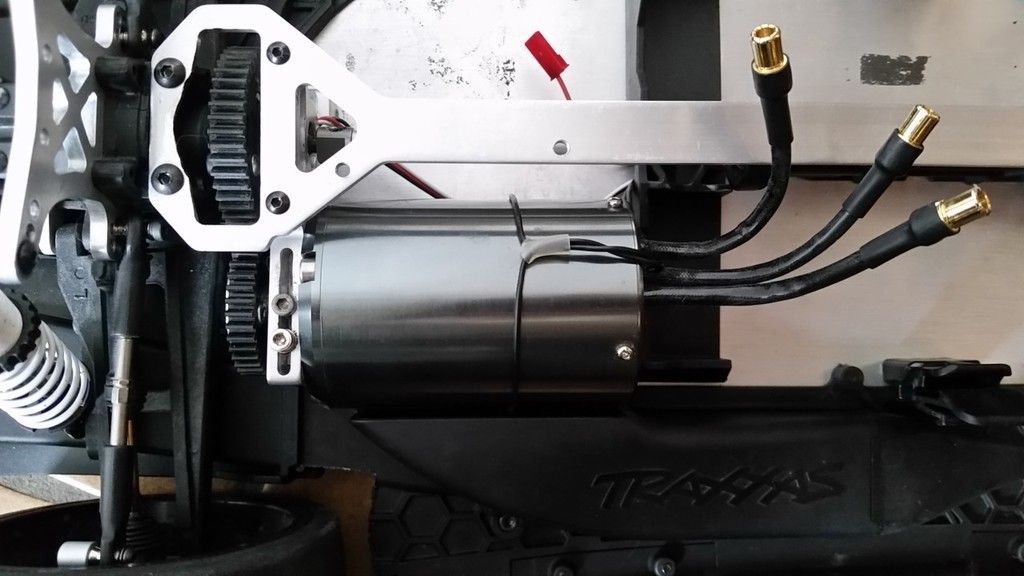

Finally put the Trackstar ESC and the Turnigy XK6582 900KV motor in the XO-1. Luckily, the 56mm motor fits without any special motor mount, just had to drill two additional holes into the stock mount. The ESC mounting plate also fits the holes already in the chassis

Added three 1000uF 35V Low-ESR caps and removed the cooling fan (wanted to add bigger fans later). Used the 46t XO-1 spur gear and a 36t Revo spur gear with an adapter as a pinion gear. With the 4.29 inch XO-1 tires that translates to 112kph/h unloaded with 3.7V per cell. Well, it didn't turn out too good. When I switched on the Traxxas TQi, it wanted me to do an update. Did that. Then, suddenly during the updating process, the TQi decided it was a good idea to send a full throttle signal to the ESC. Quite scary. Luckily, I always put something under the car so that the tires were in the air. Disconnected the battery cable then and re-did the update without ESC connected using an external battery pack to power the receiver. Powered it up again, and tried to run it. It coggs like crazy, it's almost impossible to get it moving. Motor, ESC and cables stay cool though. Not sure why that is, hopefully it's not because I damaged the ESC by pulling the battery lead when it was running unloaded full throttle (?) Or maybe it's just not "compatible" with that Turnigy motor? I guess I have to try it with another motor ...

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

05.18.2015, 01:35 PM

Ah crap man, sorry to see you're having bad luck with this (too)..., looking forward to seeing you tackle this. Curious how things will go with a different ESC. You have a spare Mamba laying around for a quick test?

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

05.19.2015, 10:33 AM

Unfortunately, no. Two Mambas in the twin and the third is in the Slash again (I put in the 1717 and Mamba so I can drive while the Alienpower is being repaired).

Hopefully we get the VESCs soon, then I have a spare Mamba again :) |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 235

Join Date: Nov 2012

Location: The Netherlands.

|

05.23.2015, 03:03 PM

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

06.16.2015, 10:06 AM

Hey man, curious how your motor is going to hold up. Mine smells like a BBQ gone bad :D... You probably know a bit more on what 56/58 mm motors have been working well in XO-1s, so let's say, "hypothetically" :D, you would be looking for a replacement for the 5682, any idea what you would be considering?

Anyway, sorry for polluting your thread man, just like to bounce some ideas with you. Cheers! |

|

|

|

|

|

(#12)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

06.16.2015, 12:59 PM

Hmm, crap that yor motor didn't last long.

I think I know no more than you. Leos are not very good is my feeling, have heard reports on my local track that the Ripper 2000kv in various Thundertiger cars gets hot and doesn't hold up. And from what I see from online pics they don't seem to be very high build quality. Your experiences were also not good (regarding efficiency). Have also seen some people with the 56x82 1360kv Leopard in the XO-1, but somehow nobody posted any real info on them. IIRC, Othello ran the Toro Beast sometime ago in a 5th scale, maybe ask him or search on the offroad-cult forum. Personally, I'd take a TP58xx around 90-100mm long (I'm too lazy to look up their weird model numbers now ;)), with a KV that gives around 30k RPM, but I have no idea if that would be a good setup. Not sure if that 30k RPM rule of thumb also applies to larger 6-Pole motors... Oh, regarding Alienpower: I got my stuff back finally. The broken ESC and the motor is exactly like I sent it to Bruno, no work done there. But Bruno said, there was one sensor defect in the motor and also something with the ESC and that he would repair it. Later then he told me, there was too much modifying done on the motor and ESC to be repairable (nope...) and he would send a new ESC. Well, the ESC was the package, but only a non-sensored one. And the program card is still missing, got another USB adapter instead. Definetely not recommended. |

|

|

|

|

|

(#13)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

06.16.2015, 02:17 PM

Yeah, I hope you can have some more fun with it. It seems the cheaper motors (Turnigy, Leo, Toro) with low kv have quite low Current ratings, mainly depending on higher Voltage to produce enough Power. The TP motors are specced a bit higher Current-wise for same kv/size combos. I thought I could keep the Turnigy happy with some cooling, but the 106 A rating seems quite realistic. If you want to try a higher Voltage on yours to see if you can keep the Current low enough, you can have my rotor as a spare whenever the post stops striking.

I asked Vedder already if he can say anything about generalizing that 60k electrical RPM as optimum trade-off point between copper losses (I^2*R: high at high load - low RPM) and non-copper losses (Eddy Currents, hysteresis and whatnot: high at low load - high RPM), as he explicitly mentions on his site that it comes from his experience with 14-pole, 50-60 mm dia outrunners. Curious if he can elaborate a bit more on the principles, but the thing for our RCs is that we typically go through the whole RPM range constantly anyway, so there's a constant change in the dominance of the copper vs. non-copper losses, depending on in what phase of the run you are... although that's my noob thoughts on it :). I'll have to give the motors some thought still, but I am realizing Current rating is not as unimportant and can't be boosted as easily with aircooling as I thought. Thanks for the info! |

|

|

|

|

|

(#14)

|

|

|

RC-Monster Admin

Offline

Posts: 10,480

Join Date: Feb 2005

|

06.17.2015, 09:53 AM

At some point the wire thickness and resistance plays a part. No matter how hard you cool it. :)

That optimum point; I think it might be a bit more complicated and setup-dependent. Artur could elaborate on that much better than I ever can. It also depends on timing. These new controllers with a timing-boost should be able help to get a higher top-end as well (I mean the ones that up their timing towards the end of the end-rpm) Never found a movie on youtube to back this theory though |

|

|

|

|

|

(#15)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

06.18.2015, 08:42 AM

Quote:

Maybe I should have looked into it a bit earlier, but after burning up the Turnigy, I got my crayons out and made some graphs to get a better understanding of how much Power is actually required to obtain a certain speed, within a certain time, or distance; thought I’d share it here for later reference and for anyone interested. Basically there are 3 types of Forces at play when accelerating to a certain speed:

Power = Force * Velocity, so from these Forces, we can get an idea of the Power requirements. The first graph below shows the Force and Power components as function of speed for a 5 kg RC, with 30cmx15cm frontal area (yes, my GT2 :)), accelerating at 10 m/s^2 (based on Lizard’s 1717 Slash: 0-150km/h in 4 seconds) through standard airmass. Drag coefficient, Cd, is guessed to be 0.35, same as the default in BrianG’s online calculator. Combined friction and rolling resistance coefficients are the biggest ‘fudge factor’ in the model. I chose them to have the Drag and friction/resistive Forces cross-over at ~50 km/h - just a shot from the hip, no idea how valid that is. The model is just a very simple and straightforward approximation, based on constant acceleration to top-speed (been way too long since I bothered with differential equations :D). In reality, the maximum traction Force the tires can put on the road is limited obviously, so the net longitudinal Force that is available for acceleration, will be limited and, in addition, will reduce with increasing speed due to the growing of the velocity dependent opposing Forces. Dashed lines in the graphs are the individual components (acceleration: a, Drag: D, friction and rolling risistance: f&r), solid cyan lines are the totals; solid magenta lines are totals minus acceleration, so representing the constant velocity Force and Power requirements. You can see how much the acceleration part actually contributes to the total Power requirements, and this model does not even take into account the (acceleration of) rotational masses (just needed a quick fix, might look at that later… well, probably not :D). Accelerating slower would lower Power demands, but running-space would become an issue then quickly. Even with 10 m/s^2 (about 1g), it takes about 100 m to accelerate from 0-160 km/h (100 mph). 0-200 km/h would take ~155 m… so accelerating slower would leave very little time for driving at top-speed (and getting a good reading of it out of a flimsy 1 Hz GPS logger to brag with on the interwebz :D).  Next step is taking into account system efficiency, also a bit of a ‘fudge factor’. After some tweaking and comparison with results of BrianG’s calculator model, I put efficiency at 69%. Main difference with the scriptasylum model is that that model seems to levy the friction and rolling resistance into the 'overall efficiency' (from input to usable output Power). If I put the friction and rolling resistance coefficients in my model on zero and take an overall efficiency of 63.7%, it seems to produce the same results as the online tool with electrical efficiency set to 85% and 4WD drive configuration - at least for the couple of speeds I checked, in the range that I’m interested in. The graph below shows the electrical Power and Current (@6S) requirements as function of speed. Based on these approximations, at 6S, it would take about 217 A to get the 5 kg example car with 10 m/^2 to 160 km/h; sustaining that speed would only take 72 A. Continuing up to 200 km/h would take 315 A , plus/minus ~30 A for a kilo more or less and 135 A in steady state. Seems that beyond 160 km/h, things are becoming a bit more tricky.  Long story short: I guess it takes at least a 220-250A motor to be able to do 160 km/h (100 mph) comfortably and reliably with a low-profile 5 kg car on 6S, which also explains the premature death of my 106A Turnigy. I think gearing the Turnigy in your X0-1 for 100 km/h might even be on the heavy side for it Lizard, unless traction sucks and you can’t get near 10 m/s^2 acceleration... good thing it was only 10 bucks :). Anyway, cheers! |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode