|

Insides of a Feigao motor |

|

|

(#1)

|

|

|

RC-Monster England!

Offline

Posts: 425

Join Date: Jun 2005

Location: North Devon, England

|

Insides of a Feigao motor -

12.28.2005, 09:14 PM

Hi, my 8L keeps falling apart (still need to find a way to hold it together..maybe going to buy some epoxy this week to try with it).

But what I've noticed is that part of the windings has like a ridge in it, where it goes higher than everywhere else, right infront of where the 3 windings leave the can. Its been like this since the day I brought it. Is this normal? I've attached a pic, its circled in yellow, sorry its not very well focused. This motors has about 5 mins total drive time on only 9 cells so I'm not sure if its affecting it. I don't want to run it again if its been mis-wound or something, and obviously I need to glue the endbell on as well before I can test it. Thanks. |

|

|

|

(#2)

|

|

|

RC-Monster Captain

Offline

Posts: 2,745

Join Date: Mar 2005

Location: Saudi Arabia

|

12.28.2005, 09:26 PM

Well, if you have found it in this condition then leave it as it is and get a L size clamp type heat sink from Mike which has the ability to hold the rear end bell of the motor tight via screws. It costs 30 dollars.

Nice to meet you! |

|

|

|

|

|

(#3)

|

|

|

RC-Monster England!

Offline

Posts: 425

Join Date: Jun 2005

Location: North Devon, England

|

12.28.2005, 09:34 PM

Unfortunately Mikes clamp won't fit onto my car (approx 1/9 scale custom chassis RC10T2). Not enough space around the motor due to the gearbox. I'd have to trim it right back which would be a lot of work.

|

|

|

|

(#4)

|

|

|

RC-Monster Captain

Offline

Posts: 2,745

Join Date: Mar 2005

Location: Saudi Arabia

|

12.28.2005, 09:40 PM

I believe it will. Be sure to take out the motor gaurd of the T2 since you will not need it anymore and put the heat sink backwards of the motor ( the fins should be at the position of the motor guard).

Nice to meet you! |

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

12.29.2005, 02:02 AM

I've used 5 minute epoxy to glue the endbell on my 8s motor. Its been holding for lots and lots of runs now. I tried to take my endbell off the other day and couldn't get it to budge.

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Mod

Offline

Posts: 6,254

Join Date: May 2005

Location: Baton Rouge

|

12.29.2005, 02:41 AM

just tap the shaft with a hammer and it should just pop the end off.

|

|

|

|

(#7)

|

|

|

RC-Monster England!

Offline

Posts: 425

Join Date: Jun 2005

Location: North Devon, England

|

12.29.2005, 07:01 AM

captain harlock, thats a good idea..only problem is then I have no rear bumper, and even though the car weighs quite a bit it still likes to wheelie once in a while. I'm thinking about fabricating a new rear bumper out some scrap alloy so I guess I could design it to go further back, which would allow the RCM heatsink to sit there.

The epoxy idea is what I was going to run with, but I don't really like the idea of getting that stuff near my motor, I tend to naff up things like that. Thanks for the suggestions guys :) I am just a bit concerned about the winding because every other picture of a feigao i've seen didn't have the winding poking up there, normally its flush with the rest of it. |

|

|

|

(#8)

|

|

|

RC-Monster Mod

Offline

Posts: 2,487

Join Date: Feb 2005

|

12.29.2005, 07:32 AM

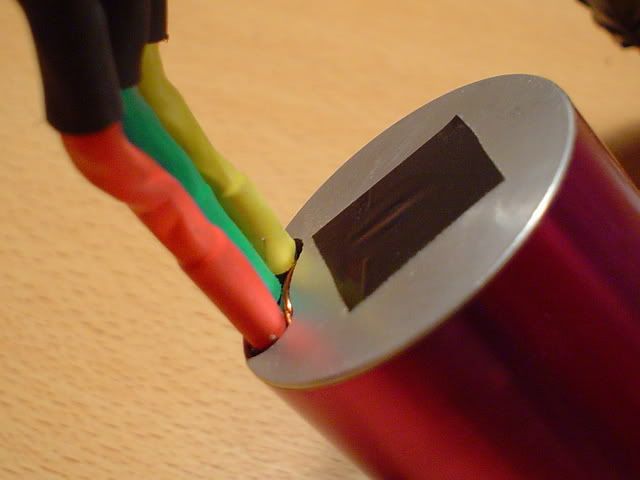

You mean your winding is poking out like this:

? |

|

|

|

|

|

(#9)

|

|

|

RC-Monster England!

Offline

Posts: 425

Join Date: Jun 2005

Location: North Devon, England

|

12.29.2005, 07:48 AM

Yep its exactly like that, just yours pokes up higher than mine by only 1mm or so. Is this normal or something to worry about?

|

|

|

|

(#10)

|

|

|

RC-Monster Mod

Offline

Posts: 2,487

Join Date: Feb 2005

|

12.29.2005, 08:04 AM

Well, it isn't normal. But for as long as the thin insulating layer of the strands is still intact, it's nothing to worry about. You could check the resistance between the wires and the can. If you get a reading, something's wrong.

The motor on the pic is still going strong. |

|

|

|

|

|

(#11)

|

|

|

Guest

Posts: n/a

|

12.29.2005, 12:35 PM

As far as the epoxy goes, I just put a thin layer on the endbell then slide it back into the can. You really can't hurt anything. just be sure to only use a small amount.

First time I epoxyed mine it only lasted about a month. The second time it stuck really really good. Btw, I tried tapping on the shaft to get the end bell off, at a point I felt like I was going to damage something so I had to take off the shaft side end thingy. |

|

|

|

|

|

(#12)

|

|

|

COOKIES!

Offline

Posts: 1,310

Join Date: Mar 2005

Location: England, York

|

12.29.2005, 01:47 PM

Sort of looks like a bad motor design to allow that, hopefully it won't happen to me.

// Dafni - good focus on that close up shot! |

|

|

|

|

|

(#13)

|

|

|

RC-Monster England!

Offline

Posts: 425

Join Date: Jun 2005

Location: North Devon, England

|

12.29.2005, 08:15 PM

OK I'm going to buy some 5 min epoxy tomorrow and get it sorted. Glad to hear the winding isn't likely to cause a problem, all the insulation should be intact as I've not scratched it or anything.

Thanks. |

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode