|

Battery Idea |

|

|

(#1)

|

|

|

Guest

Posts: n/a

|

Battery Idea -

02.24.2009, 09:50 PM

I have heard some of the guys that race buggies and truggies complain about the hassle of changing batteries in a timely manner using the Losi 8 battery holders with the 3 velcro straps. I dont use straps for my batteries but I lay a strip of female velco in the bottom of the battery tray and use a strip of male velco on the bottom of the pack. It holds well for me and less work to change batteries. The only negative I have thought of is down the road the velcro might wear out but so far so good

|

|

|

|

|

|

(#2)

|

|

|

Yip Yip Yip...

Offline

Posts: 1,489

Join Date: Aug 2007

Location: Australia

|

02.25.2009, 02:08 AM

Surely the batteries could be ejected in a big crash.

Mini-T Pro: Micro Pro 6800kv, Lipo, HS-81mg, Dirt Hawgs M18MT: Quark 33A, Y22S 6000kv, FP 2s Lipo LRP S8-BX: RC-M Conversion, Tekin RX8 B1600KV, 6S. |

|

|

|

(#3)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.25.2009, 02:44 AM

Some sort of positive hold down is a good idea. The repeated use of large amounts of velcro will most likely distort the pack, and without a strap wrapped around the pack cell shifting becomes a big concern. Hardcase lipos are a good idea for this, but I have seen the interior construction of the losi hardcase, and am not impressed at all. No padding and the cells are just floating free in there.

I would like to see a properly designed hardcase style battery box that has 4 locating pegs, one at each corner. Fixed male bullet connectors could be mounted to a plate on the chassis pointing upwards, with female connectors on the hardcase, facing downwards, like a trakpower pack upsidedown. An over center latch would hold the pack in place, and also have a lift up device built in to release the pack when the latch was disengaged. The four corner peg design would hold the pack front to back and side to side, and the latch would keep it from coming off the pegs. The peg desing takes the load off the latch and aligns the bullet connectors perfectly everytime. 5 sec battery swaps with this setup, no problem. I need to whip up a prototype, most likely with wood blocks to show how it would work... |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 341

Join Date: May 2008

Location: grants pass Or

|

02.25.2009, 02:59 AM

the best option i could see is a battery and mount that are made for each other.... I see a hardcase lipo in which the protective shell itself is part of the holding mechanism. So latches are located on the chassis itself and the battery "clips" into the latches. If you wanted to you could even have the battery leads be located at the latch so that when you latch the battery it is automatically connected to the esc, no wires or other connections needed. obviously this would be a quick release system, and there is more that needs to be thought about but i think the general idea is good.

Slash with VXL E-revo with MMM/Teckno Nue 1515/1yf running 4s and 5s |

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 341

Join Date: May 2008

Location: grants pass Or

|

02.25.2009, 09:40 PM

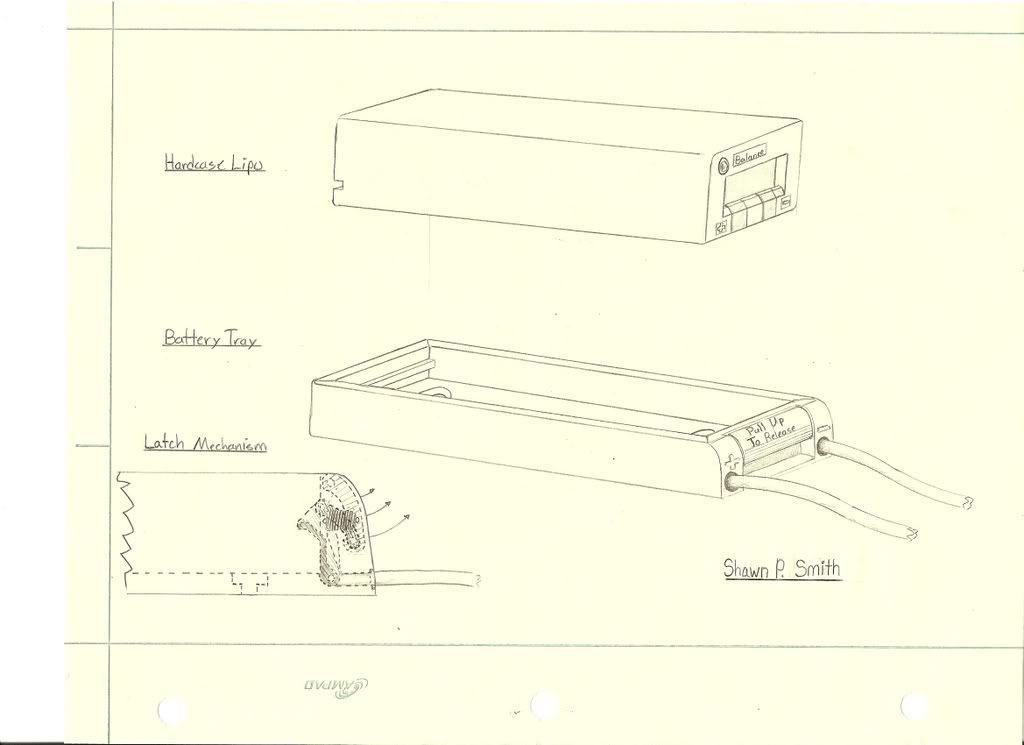

here is what i have some up with for a solution for an 1/8 scale quick release battery tray. It is actually a system that includes the battery and the tray, this way the connections are made when you snap the battery in rather than having to plug in a deans etc. This is the first version, and im sure there are improvements that can be made, but it seems like a possible idea to quicken the time it takes to swap packs.

take a look, tell me what you think. ill post some closeups to the latching mechaninism later tonight. [IMG]  [/IMG] [/IMG]As you can see the battery leads are incorporated into the latch itself, and the rear of the battery is held in place by the slot on the backside of the battery. I have sketches that clarify the latch, ill post them later. Slash with VXL E-revo with MMM/Teckno Nue 1515/1yf running 4s and 5s |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Spudgunner

Offline

Posts: 2,353

Join Date: Apr 2008

Location: South Dakota

|

02.25.2009, 10:48 PM

I thnk some kind of nested box would be nice. Just a regular battery tray with foam all around with a latching lid with foam on the bottom. That would be nice. Not as good as a hardcase latching idea, but close. Something like da shizzes disign would work great. You know what, I'm going to go into my shop and.....

|

|

|

|

(#7)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 4,236

Join Date: Dec 2007

Location: Cape Cod, Mass.

|

02.25.2009, 11:26 PM

What about a tension band....I saw a mmm esc w/ a tension band around it. You could do the same for the battery...just have a loop on an end so all you have to do is remove only one end while the other end could be fixed...I probably didn't explain it well, but, I can picture it in my head!

2. MBX-5T 1520, MMM ON 5S 3. MBX-5 ONROAD CONVERSION 1515, MMM ON 5S 4. MRX-3 ON ROAD CONVERSION 1512, MMM ON 6S 5. TEN T 2650 T8, MMP ON 3S |

|

|

|

|

|

(#8)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 341

Join Date: May 2008

Location: grants pass Or

|

02.25.2009, 11:33 PM

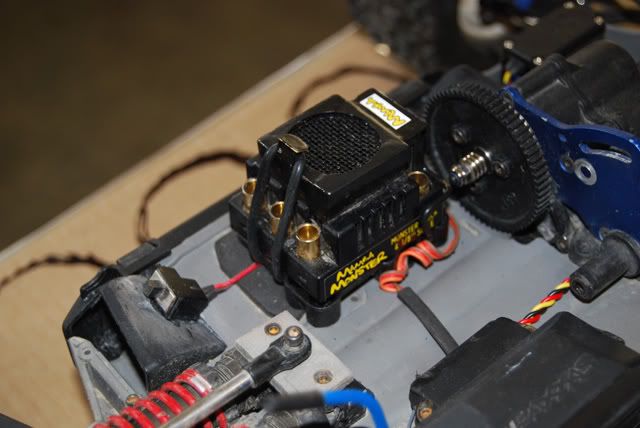

something like this?

[IMG]  [/IMG] [/IMG]  just another of my ideas, this is the second version of the design using brass angle iron. Slash with VXL E-revo with MMM/Teckno Nue 1515/1yf running 4s and 5s |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 4,236

Join Date: Dec 2007

Location: Cape Cod, Mass.

|

02.26.2009, 12:09 AM

Yup! exactly like that...just use your concept for the batts...that way it is quick and easy!

2. MBX-5T 1520, MMM ON 5S 3. MBX-5 ONROAD CONVERSION 1515, MMM ON 5S 4. MRX-3 ON ROAD CONVERSION 1512, MMM ON 6S 5. TEN T 2650 T8, MMP ON 3S |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 341

Join Date: May 2008

Location: grants pass Or

|

02.26.2009, 12:18 AM

but that would be to easy, and particularly like the idea of not having to connect the battery leads to the esc. Its all one step, when you latch the battery in you connect it to the esc.

Obviously this isn't something that most will have the capability to do... I was aiming mores so towards larger manufacturers who have the capability to produce these systems on a large scale. Who knows, maybe Mike or teckno will PM me for a business proposition, that would be nice lol:) there are definitely easier ways to strap a battery to the chassis, but i believe that this alternative will give an edge to those who are racing. Slash with VXL E-revo with MMM/Teckno Nue 1515/1yf running 4s and 5s |

|

|

|

|

|

(#11)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 305

Join Date: Sep 2007

Location: San Diego, CA

|

02.26.2009, 05:25 PM

Quote:

I also would like to say that I don't think we really need a quick change mounting system. Yes, I realize some people run 20min mains but they are really in the minority. Most clubs do 15 min. 15 min can now be done on one pack and I personally don't want any race, nitro or electric, longer than that. I especially don't want to marshall any longer than that. Once enough people get on the brushless bandwagon most tracks should have a separate class. Then we won't have to worry about stop and gos, and pushing our electronics to run non-stop for 20 mins, etc. Once summer gets here, I think we may hear about more people frying their gear, pushing it too far, and potentially scaring off newcomers to the large scale brushless scene. This is just my opinion, and I didn't mean to rant  on your thread. on your thread.

|

|

|

|

|

(#12)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

02.26.2009, 06:10 PM

Some great ideas, and valid points raised- some of you guys are mind readers I swear.

Industry standard connectors and lipo sizes are some way off really, but on an individual/personal basis, single users could make a system that works for them, laying the foundations for designs from larger corporate bodies- think RCM BL conversion motor mounts > manufacturers releasing their own electric vehicles (even though Mike's tend to be better designed and thought out  ). ).

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode