|

|

|

(#16)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

08.17.2014, 05:01 PM

Made a video with lots of onboard footage, different camera angles and places.

Hope you like it :) [YOUTUBE]EVJkGJpTDKI[/YOUTUBE] http://youtu.be/EVJkGJpTDKI EDIT: fixed the embedded video link. |

|

|

|

|

|

(#17)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.07.2014, 08:34 AM

The Alienpowersystem sensored motor and ESC for the next (and probably last) power-upgrade finally arrived :)

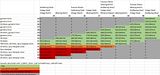

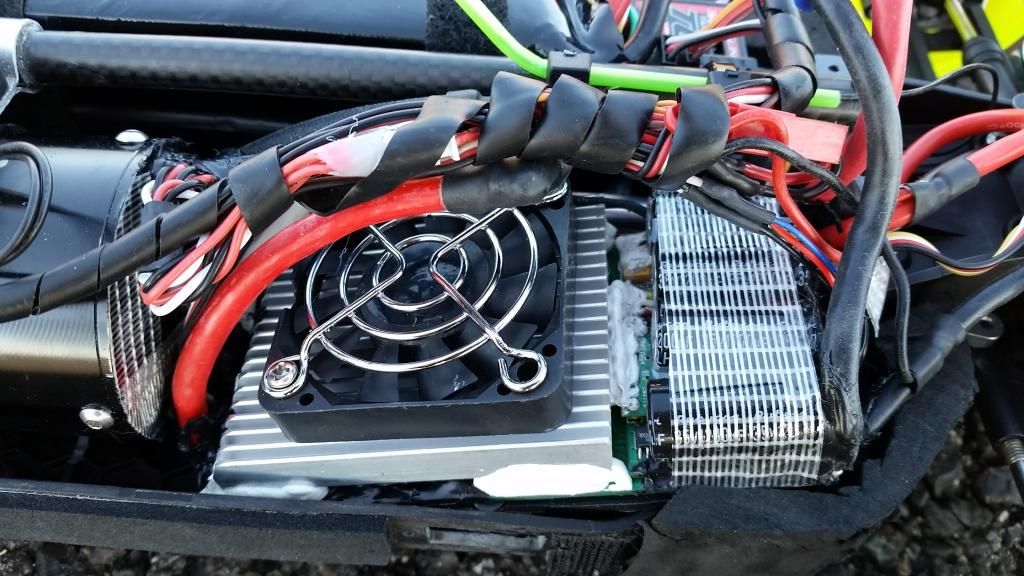

Unfortunately, the motor is not a TP5840L (57x80mm, 836g, finned can) 1260KV as ordered, but a TP5670 (55x90mm, 962g, smooth can). Bruno insisted that it's the motor I ordered and that it has 1260KV. Well, my calipers say 55x90mm, my scale says 962g and the Mamba Monster Torque Control KV-measuring says 1130KV. Now I have to re-think gearing again. But the good thing is, it seems to fit in my Slash, so atleast now I don't have that "maybe I should've gotten the bigger motor from the beginning" problem since it's already the biggest motor :) Motor case is the new 2-Part case with only the endbell removable. The rotor is somehow scratched at the ends, I wonder if they throw all the produced rotors in a big box at the factory. Nice is, that it's balanced by drilling holes in the rotor, so no "balance putty" that might come off eventually over time. The sensors fitted by Alienpowersystem seem to be glued into the motor with epoxy or something like that. Nice is, that they are "standard" Honeywell SS411A hall-sensors that can be bought everywhere for a few bucks. ESC is an Alienpowersystem 8S 250A Gen3 sensored ESC. They seem to be based on Flier ESCs but with some changes. Ordered the ESC "naked", without shrinkwrap, cables and heatsink because originally, the cables come out of the side which wouldn't fit in the Slash. But it came with heatsink mounted. Interestingly, these ESCs seem to be made by hand, only the logicboard is probably pre-assembled because of the SMD parts on it. According to Bruno, the ESC and Motor with sensors installed have been tested and "run nice and smooth". We'll see :) From a mechanical and cooling point-of-view, the ESC seems good. The Logicboard is soldered to the larger PCB and not plugged with a connector like on Castle's XL2. Heatsink was properly mounted with thermal compound (the removable stuff, not glue). All cables connecting to the PCBs have been secured with silicone. Soldering pads for the motor and batterycables are quite large and on both sides of the PCB, 8AWG cables or even bigger ones fit without problems. The FETs are some with a quite large case, not like the SMD ones found on Castle's controllers. According to Bruno, they are "Automotive-FETs" and are supposed to be more robust somehow. But it's only 18 FETs. Mamba Monster has 36, Mamba XL2 48. Well, we'll see. Caps are 4x 35V 1200uF = 4800uF. For comparison, the XL2 has 2x 680uF and 2x 560uF = 2520uF. With CC Cap Pack (4x220uF) that would be a total of 3400uF. Seems like the caps on the APS ESC are plenty, I guess I don't need additional ones then.

|

|

|

|

|

|

(#18)

|

|

|

RC-Monster Aluminum

Offline

Posts: 702

Join Date: Feb 2005

Location: n.c.

|

10.08.2014, 07:50 PM

That motor is a beast!

Slash 4x4 163mph drc rail 150 mph phildogg6@yahoo.com https://www.youtube.com/channel/UC1g...MR6SqQkehkevwA my youtube channel |

|

|

|

(#19)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.09.2014, 09:45 AM

Hehe, I hope so.

Couldn't find much information on TP Power motors, just that the boating guys seem to like them. |

|

|

|

|

|

(#20)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

10.14.2014, 10:05 AM

Hi Lizard!

Finally registered here just to be your groupie!  Anyway, was wondering if your TP also has such high magnet drag. Can you turn the shaft easily by hand? With my TP4070 it's hard to impossible to do so without the grip of a pinion on it. In comparison, the 1717 spins very freely. Wondering if that is why my motor sounds so loud in my onboard vids compared to other set-ups (including yours) I've seen (yes, I'm assuming it's not caused by be me messing up the gear mesh). Also wondering what high magnet drag would imply (if any) with respect to performance. Not sure how valid it its, but I read that it indicates the armature coils are wound around an iron core, which interacts with the magnets' static magnetic field at all times, even when the motor is un-powered. The iron core channels the electromagnetic field produced by the armature coils so it can interact more strongly with the static magnetic field, meaning motors with iron armature cores can produce more torque than motors without them. Again, don't know how valid that all is; interested to hear other's opinions. Looking forward to seeing your TP5670 powered Slash! |

|

|

|

|

|

(#21)

|

|

|

RC-Monster Aluminum

Offline

Posts: 702

Join Date: Feb 2005

Location: n.c.

|

10.14.2014, 08:51 PM

Me too.

Slash 4x4 163mph drc rail 150 mph phildogg6@yahoo.com https://www.youtube.com/channel/UC1g...MR6SqQkehkevwA my youtube channel |

|

|

|

(#22)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.15.2014, 09:26 AM

Cool, nice to have you here Dr. T.

Not sure about magnet strength and drag and how it affects torque. But what I've read is, that Lehner motors have very little magnet drag. They don't have iron cores (not sure what that is in english, it's called "Luftspule" in German, direct translation would be "air-coil"), so that thing about the iron core causing this seems to make sense. With the TP5670 I can turn the shaft by hand, but it's a lot harder than with the 1717. |

|

|

|

|

|

(#23)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 133

Join Date: Oct 2014

Location: Germany

|

10.15.2014, 02:35 PM

Quote:

|

|

|

|

|

|

|

(#24)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.16.2014, 05:31 AM

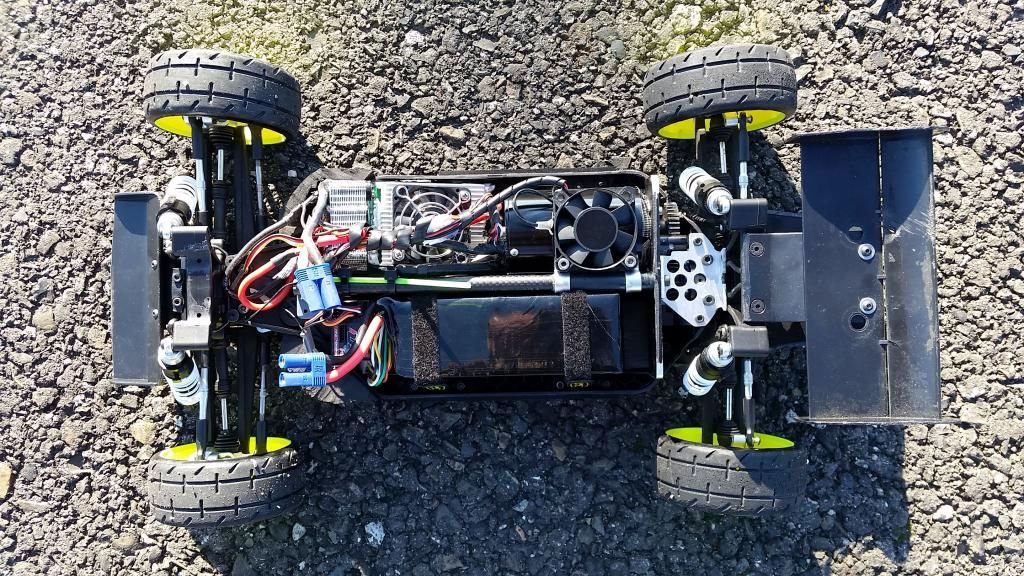

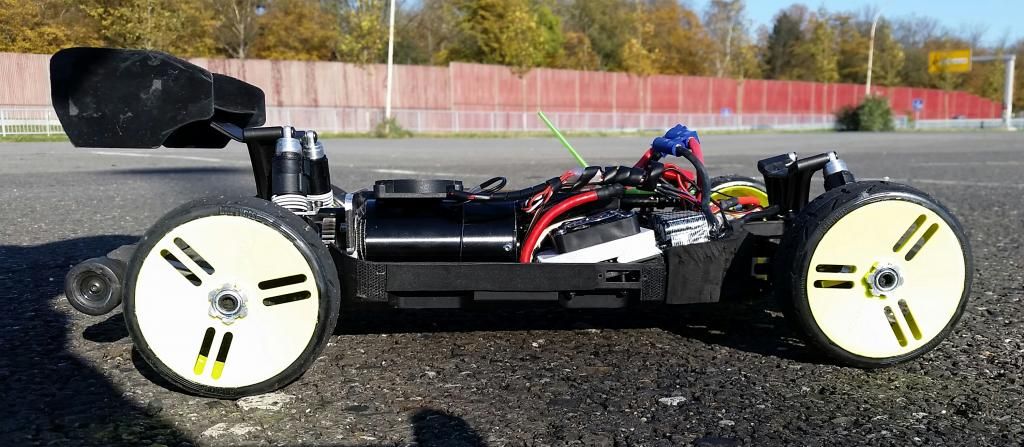

The motor is on the car now. Fits perfect :)

Motorplate is made of a 4mm thick black anodized heatsink plate I ripped out somewhere some time ago. Hope that helps a little with cooling. The plate is still a little big, will probably make it a little smaller and drill holes for weight reduction someday. Slipper has been replaced with a HotRacing Heavy Duty slipper for the Revo 3.3. This one is even bigger than the Robinson Racing Slipper. What's nice is that the slipperpad is completely surrounded by the aluminum plate, so the pad cannot rip apart like it did on the Robinson slipper which only has a hex in the middle. Now I have free choice with spur gears, the RR Gen3 Slipper was only available in 38t. Drawback with the HotRacing Slipper is that it's heavier with a steel spur. Have now used a 36t Traxxas Plastic spur to keep it light. Hope it'll hold up. Because of the motor with 1130 instead of 1260kv I had to re-think gearing. The initial plan was to grind down the motorshaft to 5mm so that I could use RC-Monster or Tekno-RC 29t and 30t pinions. Due to the lower KV the gears got bigger than planned (30t would only allow for 179kph gearing max.), had to cut the chassis and dremel the motormount quite a lot. But now I can fit 34t pinions without problems. Used a Kershaw Design 8mm Mod1 pinion, with that I can gear from 171kph to 202kph. Nice is, that I don't need to grind down the motorshaft. Bad is, that the Kershaw pinion is very heavy. I guess the best thing to do would be to use an aluminum "pinion to spur adapter", it allows to use Traxxas spur gears as pinions. Assuming that plastic holds up, this would be the easiest, lightest and cheapest solution as Traxxas spur gears can be had everywhere for a few bucks. And you can swap around gears from the slipper to the motor. Have also connected the ESC to a PC and made some screenshots of the software and settings for people interested.

|

|

|

|

|

|

(#25)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.16.2014, 05:32 AM

|

|

|

|

|

|

(#26)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.27.2014, 08:26 AM

Okay, almost done. Just the receiver needs to be placed somewhere and cables need to be tidied up.

Weight is 4240g now RTR with 8s 4000mAh Turnigy Heavy Duty Lipo made from two 4s Lipos. ESC is about 250g with cables like on the photo, Motor is 960g, battery 950g. That makes the Powertrain about half the weight of the car and the motor about 1/4 the weight. Sounds like a good ratio to me :D Gearing is a 32t Kershaw 8mm bore mod1 pinion with 36t Traxxas plastic spur. Theoretical speed with 3.7V per cell, 1130KV and the 97mm GRP tires should be 190kph or 118mph. What I don't like about the Kershaw pinion is that it's quite heavy with 47g, I hope I can use a lighter alternative later. Springs are now +20% Traxxas springs with 70wt fron and 60wt oil in the rear. Needed one more preload clip in the rear, apart from that it feels about the same as the setup before with 3.6kg car weight, +10% springs and 60wt/50wt. We'll see how it goes. Shimmed the front bearing carriers and replaced the inner and outer hinge-pins with 4mm pins from a Savage. Also installed the STRC steering. Now the front is almost slop-free. Powered up the ESC for the first time (on a bench, no running yet). What's strange is the throttle calibration. There is no "calibration-sequence" (so that the ESC can learn the ms-values for the endpoints) you can only choose "Automatic" or fixed ms values in the software. I am wondering how does the ESC determine this? I mean, when I apply half-throttle, the ESC has to know the ms values for neutral and for full-throttle, so that it can apply half throttle at a ms-value that is in the middle of these two values. Determining the ms value for neutral is easy of course, it just needs to look at the value that is present after powering-up, but how does it know what the full-throttle ms-value is? What's also strange is the throttle feel. When pulling the trigger a little, the motor starts, but then stops again, you have to pull it further to keep the motor running. Also, when pulling the throttle very slowly, the motor doesn't start at all, I can pull it (very slowly) fron neutral to full-throttle without any motor movement. Weird. I hope that is just because it was with only 25% max. throttle setting in the ESC (for testing) and that it will be alright when driven on the street with 100% throttle setting. The Castle Controller was very nice in this regard, lots of settings regarding throttle feel and very good throttle response, controlling all the power was never an issue.

|

|

|

|

|

|

(#27)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

10.29.2014, 08:14 AM

Well, as it turned out the motor and ESC came wired the wrong way (not like I asked to have it wired ...), i.e. it's spinning in the wrong direction.

Googled a bit, because I already had the feeling that just swapping two phase wires wouldn't be okay because of the sensors. Looks like I have to try six combinations for the phase wires and six for the sensor wires. So in worst case, I have to try 6x6=36 combinations :( Here is some info on sensor and phase wiring: http://www.endless-sphere.com/w/inde...rushless_Motor |

|

|

|

|

|

(#28)

|

|

|

RC-Monster Aluminum

Offline

Posts: 702

Join Date: Feb 2005

Location: n.c.

|

10.29.2014, 07:56 PM

Thats not good.

Slash 4x4 163mph drc rail 150 mph phildogg6@yahoo.com https://www.youtube.com/channel/UC1g...MR6SqQkehkevwA my youtube channel |

|

|

|

(#29)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 197

Join Date: Jul 2013

Location: Germany

|

11.03.2014, 07:14 AM

Looked again at the sensor wiring, seems it's 36 total possible combinations, but more than two of those work.

Basically, it's easy. There are six possible wiring combinations for the phase wires, and six for the sensor wires.Of those six combinations, three are working for one spinning direction and three for the other direction. Now that I already know that I have a "good" combination it's even easier. Just had to swap the phase wires and then try combinations for the sensor wires. Since I already know that I need a sensor combination "spinning" in the opposite direction, I could narrow it down to three possible sensor wire combinations. Was lucky, the first combination worked :) Finally, weather and time permitted going outside for the first run. First test was with 6s and 75% max power setting. It ran okay, but cogged a little. Increased start power in 5% steps until cogging stopped, with 45% start power there is absolutely no cogging anymore, great. Startup is a little "jumpy", i.e. you have to move the trigger quite far to get it going, and then it immediately "jumps" from zero to about 5-10kph speed. But it is able to run slow without any cogging like a crawler when releasing the throttle a little after startup. Well, not a real issue for me, as I don't drive slow anyway. Apart from the startup it runs very smooth in every situation. What I like is that it coasts very nice, i.e. after releasing the throttle it doesn't slow down too fast on it's own, similar to a nitro car with a clutch. Braking somehow doesn't work. When applying the brakes, the car brakes for a very short amount of time (1/2s maybe) and then keeps on rolling until right before coming to a full stop (maybe 10kph) then it brakes again. Tried different brake strength settings, that changed the amount of brake applied within that half second, but that's it. Thought it may have something to do with reverse, so I disabled reverse in the ESC software. After that, the ESC wouldn't run at all. It would beep like it was armed, but no reaction to throttle, neither direction. Temps after about 5mins of running were about 35C for the motor and ESC. Next test was with 8s and 75% max power setting. After 2 minutes of running the plastic spur melted, seems like the slipper was too lose (screw about 1/3 turn open). Replaced it with a 36T HotRacing steel spur and cranked the slipper nut all the way down. Seems to hold up now. After about 5mins of running, motor temp was about 45C, ESC temp 35C. Outside temp was 21C. Seems quite high, considering that it was limited to 75% and I didn't go too fast as I had no brakes. After two more minutes of running, the car suddenly stopped and did not react to throttle anymore. Receiver was blinking fast red, thought it was a receiver issue first, but then noticed that the fan on the ESC also stopped working. Re-plugged everything, ESC startup beeps are there, but receiver still blinking and ESC fan not running. Went home and tried another receiver, same problem. Then measured the voltage coming out of the ESC BEC. It's only 3V, seems like the BEC is toast :( Wanted to try an external BEC for testing, but it seems while testing my TQI Transmitter somehow died. No lights, no nothing, just dead. Now I have to wait until I get a new transmitter :( [youtube]C7noDHnsWjU[/youtube]

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode