|

|

|

|

|

(#1)

|

|

|

RC-Monster Aluminum

Offline

Posts: 905

Join Date: Aug 2007

|

12.03.2007, 02:18 AM

I can barely imagine what kind of power a 4030 will put down. It will be interesting to see if the gearing or rollout threshold for startup will can be changed much with the extra motor size. Getting any more speed from your revo as-is takes a taller tire,hotter wind motor, or higher voltage. I really think the simplicity will help understand the limits of sensorless motor control.

|

|

|

|

|

|

(#2)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.03.2007, 09:03 AM

Quote:

It was surprising to see that the 4130 was only generating 2.9 volts at 930 rpm. I wonder what the lower and upper limits of the EMF feedback "window" really is? I'm sure the design of the ESC has some reasoning in it that matches most setups out there. There is a resistor in each of the 3 lines on the EMF feedback leads going to the brain board. I'm sure those are there to raise the upper limit of the EMF "window", but it also raises the lower limit that can be seen by the ESC. I wonder what would happen if those were removed? I believe they traded some "lower" to increase voltage operating range. The Quark tends to cog more on fresh fully charged 6S Lipo. I'm sure it has to do with this. Removing those would probably make for better startups, but also might lower the voltage operating range to perhaps 4S or 5S. I have a Quark 125 Monster Pro on the way now. Once it gets here, I may try to bypass those resistors on my 80 amp ESC as a test. Do something that is reversible just to see. I need to ask Griffin about this. Vehicle weight has alot to do with this also. The ESC blindly (no EMF feedback) sends a "kick in the pants" to the motor for startup. If vehicle weight or gearing is so great, that the motor doesn't give the vehicle enough movement to get some EFM return, the ESC is "lost" as to armature position. This is when cogging occurs. The 4130 did startup better than the 4120, but the top speed wasn't there so I switched. This leads me to believe that kv and stator length has something to do with this. Aaaah, look at this. "Kv = RPM / voltage" I spun the 4130 at 930rpm with a drill. It was feeding 2.9 volts into a volt meter on the AC scale. 930rpm/2.9volts= 320kv" With the higher kv of 660, using this formula, the 4120 at 930rpm is only going to generate 1.4 volts.  The first EMF pulses must be VERY small and hard to see. Longer stator/magnets/winding changes that. Hmmmm............This is where experimenting with different winding configurations could pay off.

|

|

|

|

|

|

|

(#3)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.03.2007, 09:25 AM

AXI emailed me back!

"both ways are possible to provide you with set of parts for this motor. This we make really rare but in case you have it for some special application it is possible. Or if you tell use the winding we can make for you custom made winding." What wye wind should I get to make 700kv? Here's what I wrote them back. "With a Wye wind, the torque is 1.73 times greater than the Delta wind but the kv is 1.73 times lower. If we negate the kv loss with fewer turns, will the torque bonus still be there? Excellant! How much for the custom wind 4130? How much will the kit be?" This should be interesting!

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

12.03.2007, 10:35 AM

get a vid when shes done!

|

|

|

|

(#5)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.03.2007, 07:21 PM

Well the custom wind from the manufacturer is pretty much out of the picture. I can buy two regular motors for what they want for that.

I have a second 4130/20 here that I can use to experiment with different windings. But how do I get this stator off the bearing holder? Hmmm, I wonder if I could trim the stationary endbell down to allow enough room to do the winding and make the terminations? I was thinking about modifying a pair of needle nose pliers to aid me in this. Grind the teeth off the jaws, then wrap them with black tape. I know I can't tear the insulation on the winding wire as this will create shorts. |

|

|

|

|

|

(#6)

|

|

|

RC-Monster Aluminum

Offline

Posts: 905

Join Date: Aug 2007

|

12.03.2007, 09:24 PM

Get some kits from Lucien. Although he doesn't have any 40 series kits yet, I know I could get just the stators and bearing tubes from him. Then you could just swap out the bell from stator to stator and save some cash on buying magnets. You would need to use a specialized bearing puller to get the stator off the bearing tube otherwise.

|

|

|

|

|

|

(#7)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.03.2007, 09:35 PM

Quote:

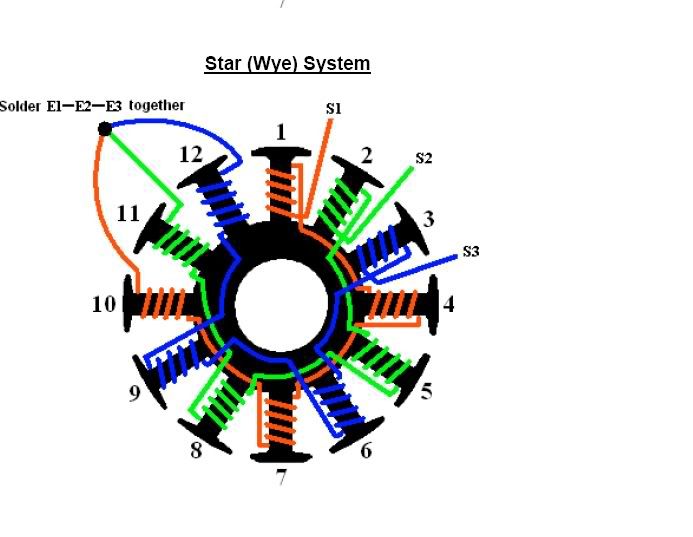

With this first round, I'm gonna try to rewind this second 4130 that I have. I would rather stick with AXI to start with, because I don't know how hot this is going to run. The cooling fan will help with that since it moves alot of air. I'm thinking about a 6 or 7 turn wye termination with as many strands of 22Ga that will fit. Once wound, I can do the spin voltage test to get a close approximation of the kv for the wind. I intend to wind it just like this.  Any thoughts? |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode