|

|

|

(#11)

|

|

|

The Big Cheese

Offline

Posts: 125

Join Date: Mar 2009

Location: Georgia, USA

|

03.18.2009, 06:51 PM

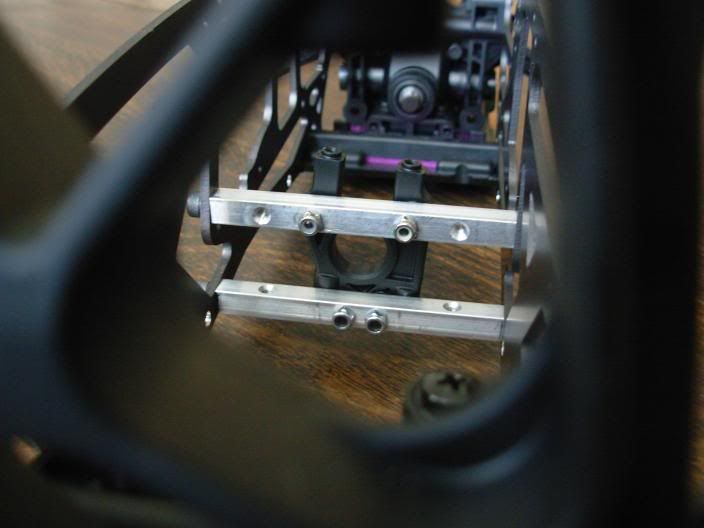

I got the front CD mount braced in, and Im really happy with how its turning out. The spur gear will hang out the underside of the chassis a bit, but I can make a skid plate to protect it. Before you ask, yeah I know the plastic piece is crooked, it had to be that way to get the screws how I wanted them. There is JUST enough clearance between the cd cups and the braces to be comfortable. Cant wait to get the last 2 braces and finish this up.

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Threaded Mode

Threaded Mode