|

|

|

Try these |

|

|

(#1)

|

|

|

JERRY2KONE SUPERMAXX

Offline

Posts: 3,452

Join Date: Sep 2006

Location: HAYMARKET VIRGINIA

|

Try these -

09.05.2011, 03:59 PM

You may want to try using a better grade of machine screw/bolt to avoid having this kind of problem. I have gone through every sort of hardware since getting seriously involved in R/C from stainless steel, to titanium, Tonys screw, Hexhead screws, as well as all grades of black steel screws. The best screws I have found are the grade 12.9 hard steel screws that you can find at a few hardware suppliers around the globe. The link below shows you just some of the screws I now use, and I have yet to strip or break one of these. If you want the best results, then you have to use the best tools and hardware to hold your expensive toy together. Lito turned me on to BoltDepot.com a couple of years ago, and I have not been disapointed yet. I have about $1000 in hardware from them in my R/C storage bins, and I have changed out everything on my trucks using their 12.9 grade screws. Everything looks clean, and everything works the way it should. These are hard steel and if you break these then you are torquing things down way to hard. If so start using a torque screwdriver to measure and torque your connections to the right level.

http://www.boltdepot.com/Metric_sock...m_x_0.5mm.aspx |

|

|

|

|

|

(#2)

|

||

|

Guest

Posts: n/a

|

09.05.2011, 04:13 PM

Quote:

|

|

|

|

|

Same |

|

|

(#3)

|

|

|

JERRY2KONE SUPERMAXX

Offline

Posts: 3,452

Join Date: Sep 2006

Location: HAYMARKET VIRGINIA

|

Same -

09.05.2011, 04:33 PM

The grading system works pretty much the same. Using stainless steel screws is just asking for trouble. Stainless steel is soft and will strip, twist, and shear off even under moderate torque. If you use a stainless steel screw, remove it and use it again it will break sooner or later. Under industrial rules it is never good practice to re-use hardware of any kind for safety sakes. Like I said I have not had a 12.9 grade screw break yet, and as long as you use reasonable torque they will hold up very well. Tonys screws are stainless and they look nice and shiny. If that is your goal and you want to continue using them, than I would say start using a torque screwdriver to avoid twisting off anymore heads. Still the socket/allen heads are too dammed easy to strip out. Why put up with it if you don't have to? Everyone has to work with what makes them happy. For industrial standards using steel screws in aluminum hardware also has its drawbacks, but as long as you are using BLUE loctite for moderate holding, and RED loctite for more permenant holding you will have no problems. Metal to metal fastening is not recommended. Good luck with that.

|

|

|

|

|

|

(#4)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 401

Join Date: May 2011

Location: Houston Tx,USA

|

09.05.2011, 08:17 PM

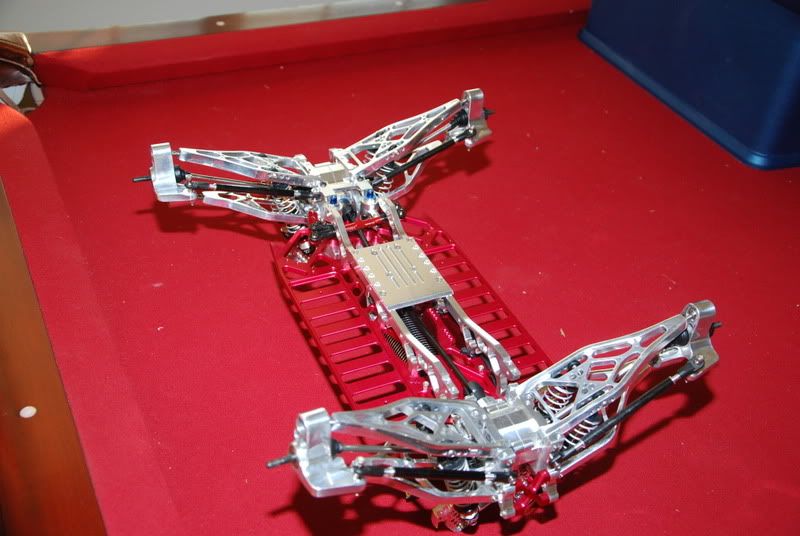

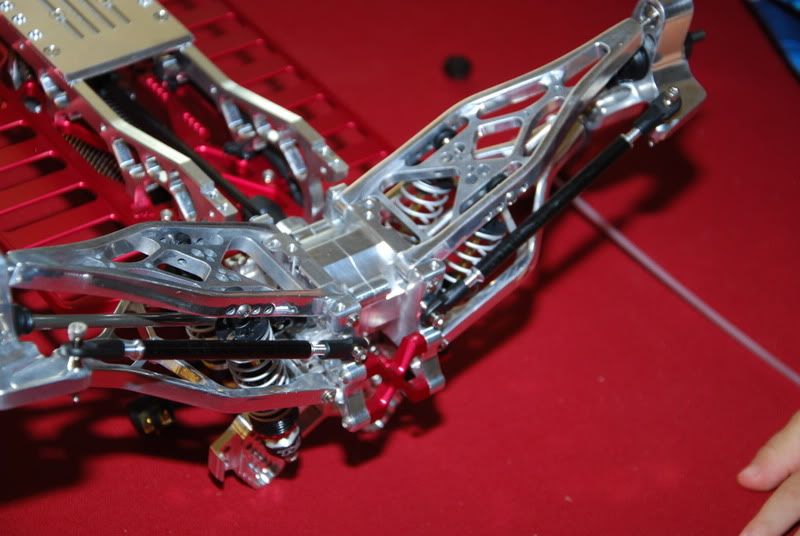

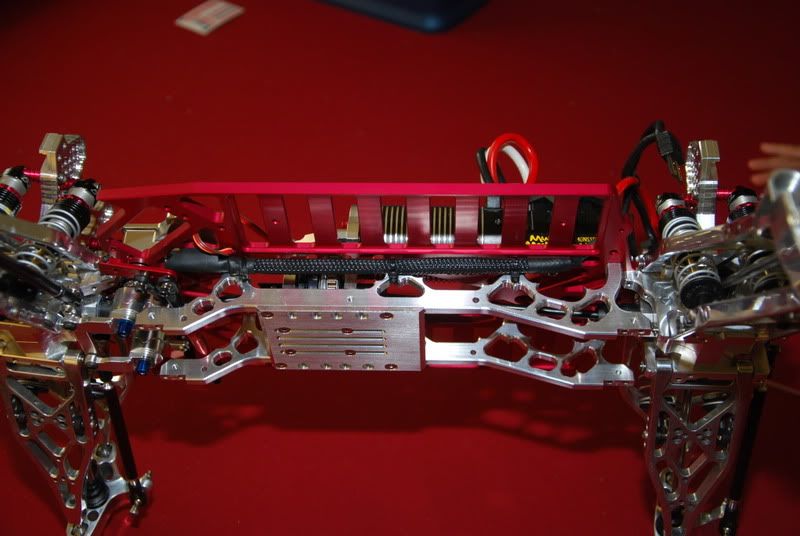

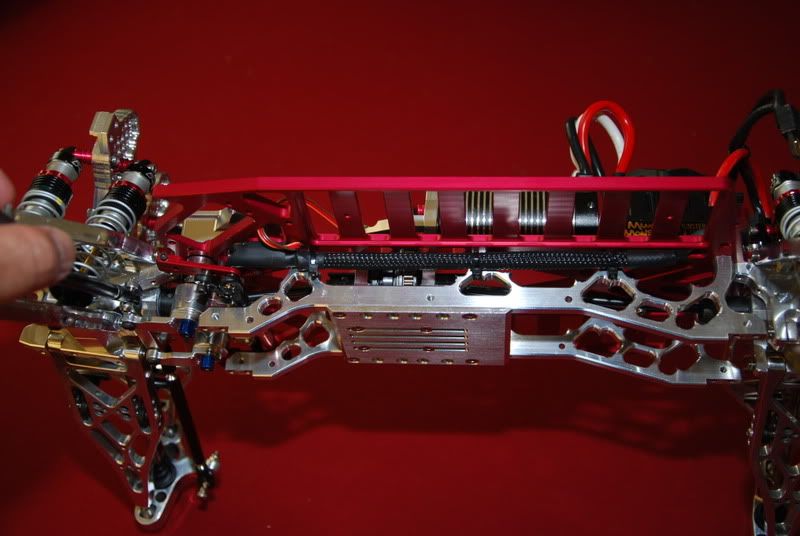

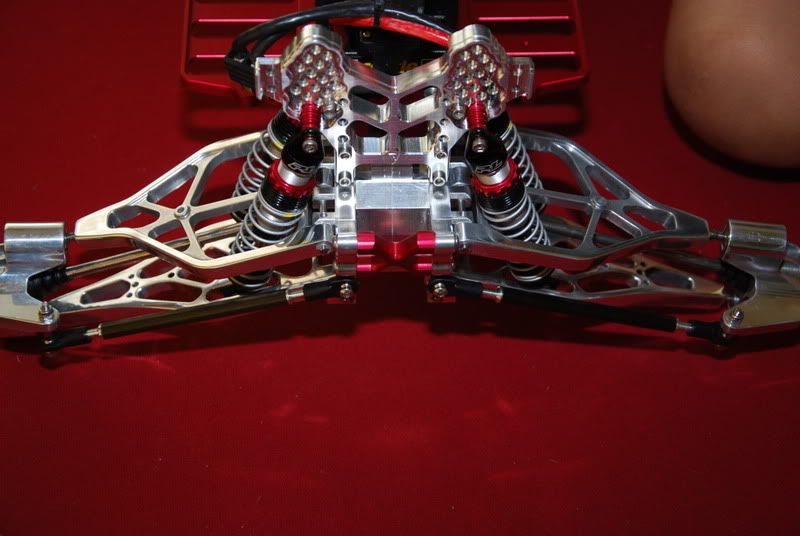

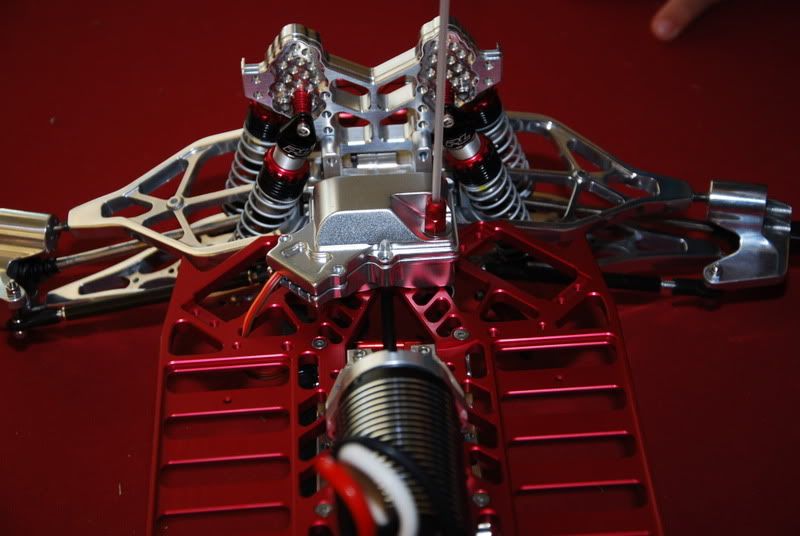

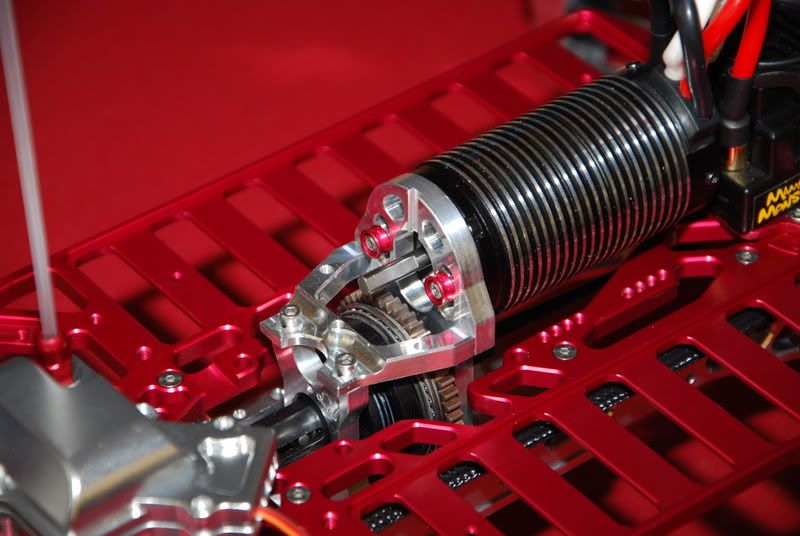

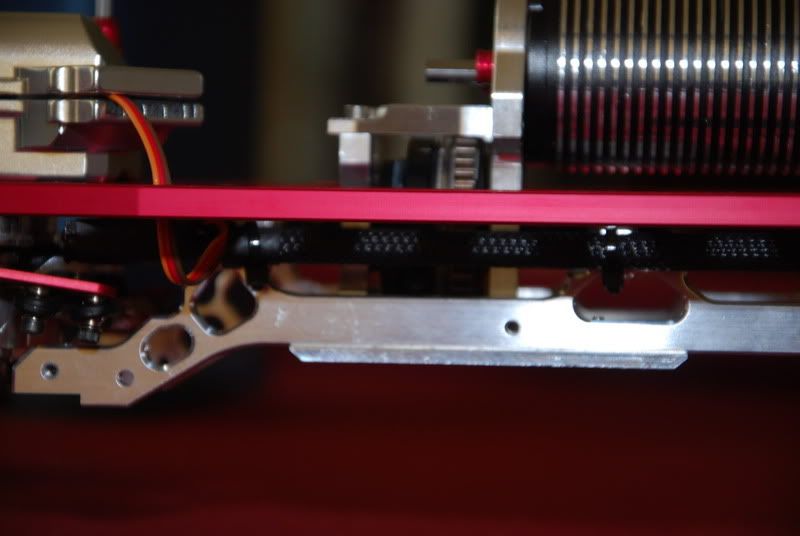

OK, some progress and a small set back. No big deal I cut the rear carbon fiber rods a little too short, and I will have to get another set. I did manage to get the ESC mounted and I bolted up the motor (no pinion gear yet I'm not sure which one I will go with). I started running the ESC wires but ran out of shrink wrap. I will finish that tomorrow. I used a tube from an old spray bottle cut it down the middle and then covered it with some wire loom that I found a local computer store shrink wrapped it at both ends and this is what I have done so far. The wire that is showing is just temporary. I'm still waiting for the tires to cure. I think I will wait for 24 hours. All I have to do is mount the receiver and pick a pinion gear, I still have to solder traxxas ends on to my batteries and I think I will use Velcro to hold them down for now just to get this thing rolling. Here are a few pics......

|

|

|

|

|

|

(#5)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 339

Join Date: Aug 2005

Location: Indiana

|

09.06.2011, 01:33 AM

|

|

|

|

(#7)

|

|

|

JERRY2KONE SUPERMAXX

Offline

Posts: 3,452

Join Date: Sep 2006

Location: HAYMARKET VIRGINIA

|

09.06.2011, 04:02 AM

I have not used Tony's screws in quite a while, but the last time I checked his screws are stainless steel. grade 12.9 stainless steel? I don't think so. Stainless is graded on a different scale (18.8) or something like that, and like I stated previously stainless is inherently a softer material making it more prone to failure. It works great for certain large scale applications (in water) due to the fact that it will not rust or degrade like regular carbon steel will. It just will not give you the same strength and holding power either. Especially in such a small (3mm) application. Some people like having softer hardware so it is easier to remove if there is a problem. Plus it gives you that nice shiny look that appeals to others. I personally like building things to last, and resist breakage so I use the harder material. Personal preference. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode