|

|

|

|

|

(#1)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

07.03.2010, 05:06 PM

I'm very critical, as it's what I do for a living for the past 11 years.

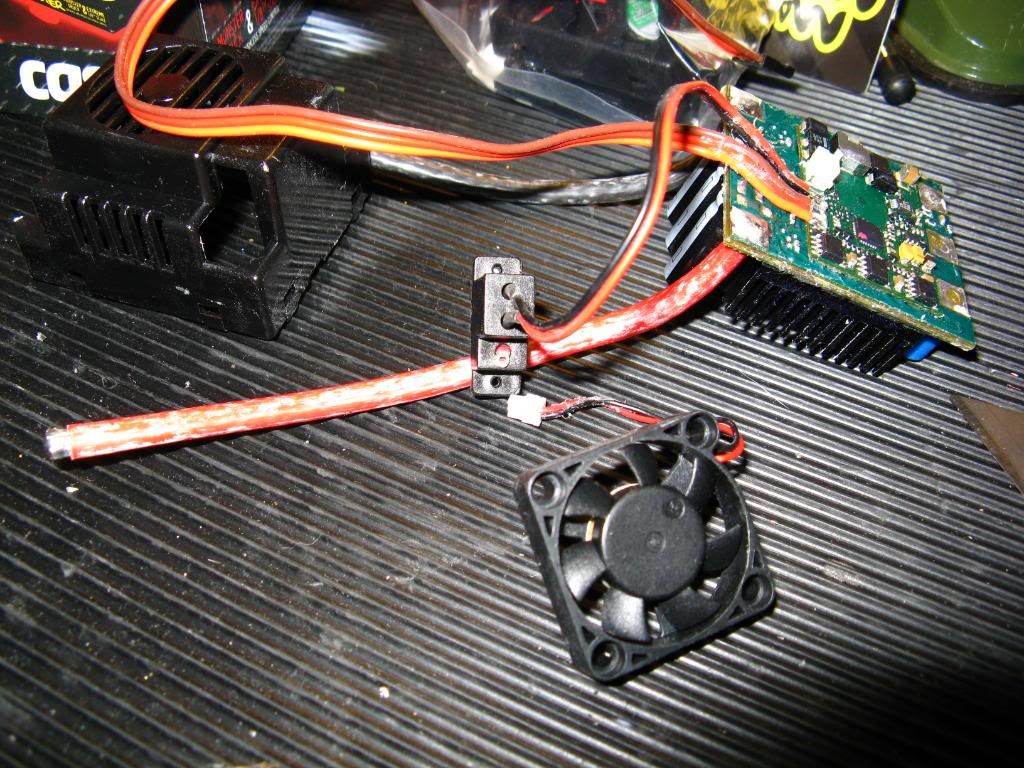

I do know that the Castle ESC's put out the power. Heck I still help peeps out from different states with their Castle ESC's for dragracing. So I'm not putting Castle down by any means. However, for 1/8 scale dragracing and speedruns(what I like to do), I want the most out of a ESC. That means proper cooling. As it sits right now with the two MMM that I have, heat dissipation is achieved by the fet board and that little patch of thermal adhesive to the heatsink. I prefer that all fets make contact with the heatsink. If you have an efficient setup, there wouldn't be a problem in it's current state. But I need max cooling in this Texas Heat. GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#2)

|

|

|

Guest

Posts: n/a

|

07.03.2010, 06:09 PM

Oh damn... I just bought a MGM ESC lol. Never had a MGM before, curious how it will perform.

I understand :) But one of those 2 goes in the TM Buggy right? |

|

|

|

|

|

(#3)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

07.03.2010, 11:03 PM

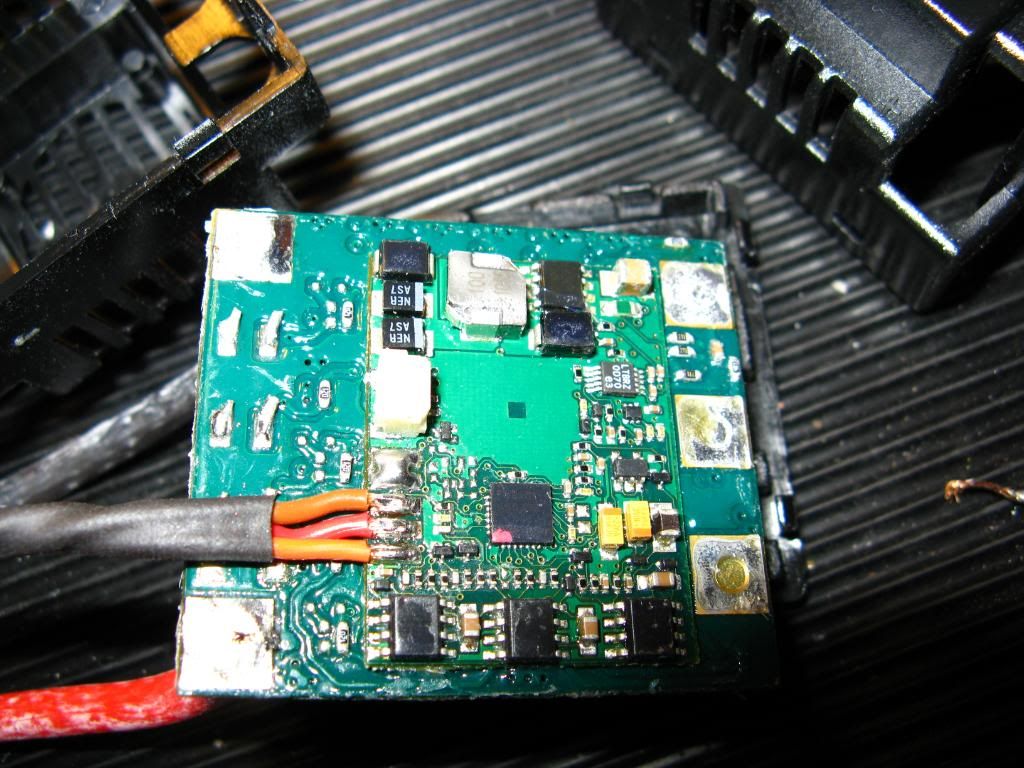

My camera is not good enough to show the gap between the heatsink and fets.

The MMM will be used in the GTP. Power, speed and brakes will be compared against the RX8. I had an MGM before. Awesome power untill one day it just smoked.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#4)

|

|

|

Guest

Posts: n/a

|

12.25.2010, 04:53 PM

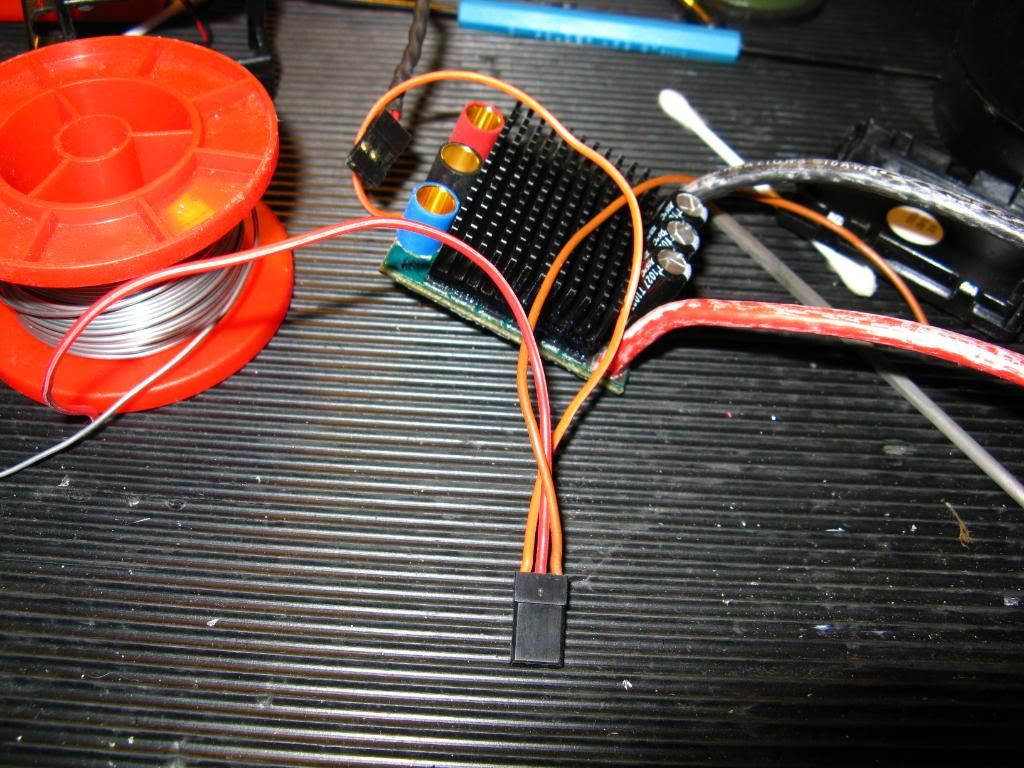

is it a short on the reciver wiring on the left one? ether way its kind of nasty soldering job

|

|

|

|

|

|

(#5)

|

|

|

Guest

Posts: n/a

|

12.25.2010, 06:41 PM

Also look at the negative wire connection it's not the same soldering as the positive one.

|

|

|

|

|

|

(#6)

|

|

|

Guest

Posts: n/a

|

12.25.2010, 07:57 PM

yeah i have seen that on discovery, but shouldent it be none ore little variation in such case?

also im sure all the small components in the board is done in such way, but it may be the wires is done some kind of manually, ether way you can clearly see the orange and red have contact. also the black and brown |

|

|

|

|

|

(#7)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 301

Join Date: Feb 2008

|

12.25.2010, 10:41 PM

The battery leads, receiver lead and switch wires are soldered onto the board by hand. This can lead to some variations of the solder connection.

Thomas Porfert Tech Support Castle Creations. |

|

|

|

|

|

(#8)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

07.04.2010, 05:22 AM

I know ideally the heatsink should make direct contact with the fets, and the glue is just there to hold it in place ( gap filler ), but I wonder if you could use some thermal glue and squeeze it into the gaps so that the remaining fets and heatsink are linked to some degree?

|

|

|

|

|

|

(#9)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

07.04.2010, 10:16 AM

I have some 3M Thermally Conductive adhesive somewhere that I could try to use.

GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#10)

|

|

|

Guest

Posts: n/a

|

12.24.2010, 04:44 PM

Any resuslts of the 3M compound?

How did you remove the heatsink? |

|

|

|

|

|

(#11)

|

|

|

2 KiloWatt RACER

Offline

Posts: 2,496

Join Date: May 2007

Location: Houston

|

12.24.2010, 04:50 PM

This is put on the backburner. Family addition keeps me too busy.

But to remove the heatsink, you can use a heatgun and a razor. GTP-Pletty Big Maxximum+RX8. GTP-C50-6L Hacker+RX8. CRT.5-Pro4+ZTW esc. 24s2p EVG SX 49.6mph Ebike. 18s4p Raptor 60mph Ebike. 11.5KW |

|

|

|

|

|

(#12)

|

|

|

Guest

Posts: n/a

|

12.24.2010, 05:19 PM

Thanks!

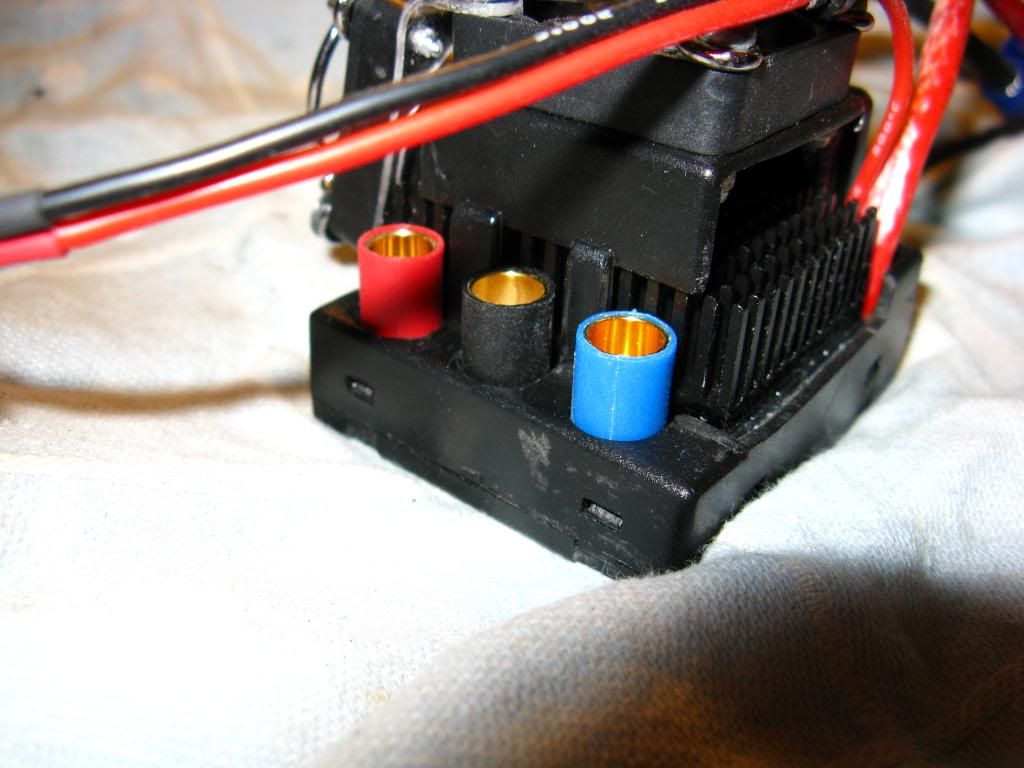

I don't like the stock heatsink mounting. Ps I've also this nice V5 board:-) |

|

|

|

|

|

(#13)

|

|

|

RC-Monster RC8T

Offline

Posts: 2,554

Join Date: Jan 2008

Location: Syracuse, New York (Camillus)

|

12.25.2010, 07:30 PM

None of it is soldered by hand. The solder is a sticky paste and when heated in an oven it flows, there will be some variations in the way it flows depending on the wires

SC10 MMPro 13.5T 2s NeuEnery 5000mah RC18T Mamba 25/5400kv 2s lipo + 6s NiMh |

|

|

|

|

|

(#14)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.25.2010, 11:41 PM

IIRC the best way to get the heatsink off is to put the esc in the freezer overnight and then a small amount of pressure between the sink and a fet should pop it off. Clean off the glue, and use thermal paste. Not sure of the brand but generally the paste has a better ability to transfer heat than the adhesive. So use anhesive on the 4 corners and paste on the rest. Also a good idea to make sure the base of the heatsink is perfectly flat, so use a good straight file or a piece of sandpaper on some glass. Use the min of paste/glue.

|

|

|

|

|

|

(#15)

|

|

|

Guest

Posts: n/a

|

12.26.2010, 06:36 AM

Thanks for also a good tip for removing the heatsink.

Mine new esc soldering job could a little better.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode