|

|

|

|

|

(#1)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

12.29.2009, 10:48 PM

I was thinking you were going to use Hyperions. Have you not had any problems with the turnbuckles or the rodends especially in the rear? The proline arms are cool to have but truetracks are incredible! I seriously broke 10-15 rear rodends and bent the turnbuckles up especially in the front. The way the truetracks work make it more durable and kinda more 1/8th scale. I can also strongly reccomend the traxxas tubes(along with 3.3 suspension of course). I use the platitum revo knuckles because they were only a few dollars more and you get bigger bearings. The rodends are beefier on the 3.3 but I was still bustin them so I modded some of THESE. They have to be cut a tad as they are too long and the hole must be made a mm or two bigger. After ~8 months I've only cracked one and replaced it before it stopped a bash session.

|

|

|

|

|

|

(#2)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.30.2009, 12:54 AM

Quote:

... The turnbuckles are great... the rod ends are real big and robust... never had to re-tune them... I have had the truck cartwheel down a ... The turnbuckles are great... the rod ends are real big and robust... never had to re-tune them... I have had the truck cartwheel down a hill and none of them have came lose... I have been considering the 3.3 knuckles though... my friend has been bugging me to get a set... so I'll look at them a little closer. Alien |

|

|

|

|

|

|

(#3)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

12.30.2009, 01:01 AM

Quote:

Get THESE and really surprise him. |

|

|

|

|

|

|

(#4)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.30.2009, 01:24 AM

Quote:

Those are some cool looking knuckles... how long do you think the bearing seats will last? my friend's have gone wobbly, and he has been shimming them to keep the bearings as tight as possible. Alien |

|

|

|

|

|

|

(#5)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

12.30.2009, 12:27 PM

Quote:

Your friends 3905 knuckles have wobbly bearing seats? Yeah I don't know. I have the RPM Truetrack knuckles(awesome, has no turnbuckles its much like rear racerX but much cheaper) in the rear and the platinum knuckles in the front. They are lasting a long time. when they go out I will buy the tekno's. I'm loving the thought of the included 8mm stub axles but I can't tell if it'll work with my TRX steel cvds. EDIT: yeah the 8mm stub axles won't work with trx CVDs. oh well I've bent one or two 5mm stubs in the past but now since I've become a better driver I haven't bent another. |

|

|

|

|

|

|

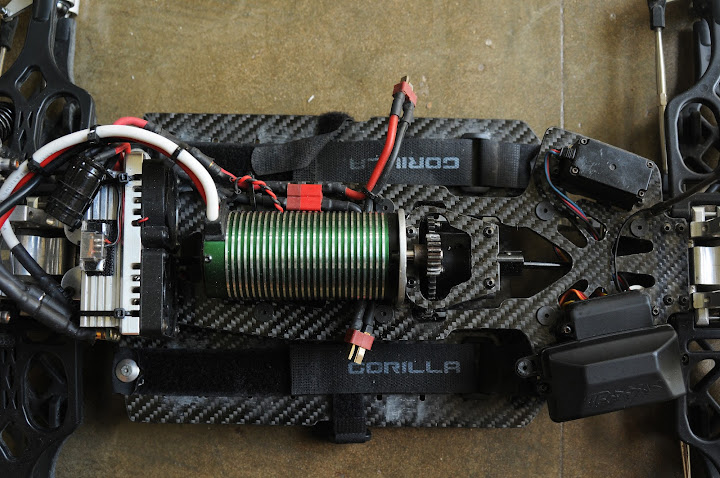

(#6)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,419

Join Date: Dec 2008

Location: Louisville, KY

|

12.31.2009, 12:18 PM

Very nice! With the length of this huge motor is there not enough room to mount the esc with fans, hitsinks, and all that like you had it? 4 poles rule! EEK NIMHS

|

|

|

|

|

|

(#7)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.31.2009, 01:04 PM

Quote:

Yep... I have two options... horizontaly with the fans facing downward and horizontaly with the fans facing the motor (this one will allow more air flow over the heatsink)... with new motor mount i think it will allow me to mount the esc inline with the motor again, but it's going to be a tight fit. |

|

|

|

|

|

|

(#8)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

12.31.2009, 05:11 PM

Ok... I made another 'test' run today with two packs... the first was not fully charged, but it had enough get the motor turning well. It's quick and smooth on power... breaking was excellent...

stopping was noticeably easier with the 1520... temps on the motor went up to 120° F and the esc 122° F (no heatsink)... I think I got about 5 minutes of WOT run time with this set of batteries... with the 'fully' charged packs I got 10 mins WOT... I pushed a lot harder with these cells and saw that this truck will be a handful when I finally get some lipos for it... I was a little aggressive with the throttle and brakes just to see how hard it could be pushed... the temps of course were a little different... 137° F for the motor and 135° F (still not heatsink). Here's the setup: Differential Ratio: 4.3 Transmission Ratio: 1 Other Ratio: 1 Spur Tooth Count: 51 Pinion Tooth Count: 15 Total Voltage: 18.5 Motor KV: 1600 Tire Diameter (inches): 5.65 Tire Ballooning (inches): 0 Motor Current Draw: 0 Motor Coil Resistance: 0 Spur/Pinion Ratio: 3.4 : 1 Total Ratio: 14.62 : 1 Tire Circumference (inches): 17.75 inches (450.85 mm) Rollout: 1.21:1 Total Motor Speed: 29600 RPM Vehicle Speed: 34.03 mph (54.67 km/h) Effective KV Value: 1600 KT constant: 0.85 oz-in/A I think when I finally put all back together, i should be able to gear up a tooth or two. The temps on esc were really good and I was quite impressed it had no thermals running without a heatsink. Alien |

|

|

|

|

|

(#9)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

01.02.2010, 02:44 PM

Continuing with the experiments... I was getting a little concerned again about the temps and them getting higher when I eventually switch over to lipos.... so I decided to make some changes

with ESC setup and pinion to see if I would get better results... and I did... I remembered when I was first testing the hacker, the 'Torque Selection' was change from 'Soft' to Dynamic Initial Torque'... So I went back through the Quark programming and changed the initial torque to 'Normal 1', one step above 'soft'... I swapped the 15t pinion for a 18t just too see what would happen... this motor had so much torque I assumed it could handle the gear up... I was not wrong about this, The motor showed off what it could really do with it's power and pulled the truck just as hard when it was fitted with the 15 tooth... Very impressive to say the least... the temps were also surprising... the esc only got to 112° F  (well it had some help from the heatsink)... I thought it would have been much higher with the (well it had some help from the heatsink)... I thought it would have been much higher with the larger pinion... the motor stayed in the high 120s  The setup: Differential Ratio: 4.3 Transmission Ratio: 1 Other Ratio: 1 Spur Tooth Count: 51 Pinion Tooth Count: 18 Total Voltage: 18.5 Motor KV: 1600 Tire Diameter (inches): 5.65 Tire Ballooning (inches): 0 Motor Current Draw: 0 Motor Coil Resistance: 0 Spur/Pinion Ratio: 2.83 : 1 Total Ratio: 12.18333 : 1 Tire Circumference (inches): 17.75 inches (450.85 mm) Rollout: 1.46:1 Total Motor Speed: 29600 RPM Vehicle Speed: 40.84 mph (65.6 km/h) Effective KV Value: 1600 KT constant: 0.85 oz-in/A   CC 1520 with a 18t pinion  I'm going to run it on 5s tomorrow and see it goes... going to also try and get some vids done too (good quality I hope). Alien |

|

|

|

|

|

(#11)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

01.02.2010, 11:07 PM

Not very... it took about 15 minutes for the CNC to get through all the shapes... removing the shapes with a dremel cutoff wheel is pretty easy... sanding and finishing didn't take

that long at all... when handling this stuff though, it's always good to be mindful of the dangers... I prefer to cut and sand it when it's wet to reduce the amount of dust floating around and getting into your longs... wear a dust mask and goggles when working with it. Alien |

|

|

|

|

|

(#12)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 279

Join Date: Dec 2008

Location: sweden/nacka

|

01.05.2010, 04:50 PM

what center shafts do you use with your CD? ordinary emaxx shafts?is it the same length?

|

|

|

|

|

|

(#13)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

01.05.2010, 05:10 PM

Quote:

I used Savage XL center drive shafts/dogbones... a perfect fit with the CD and cheap too... Alien |

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Square Tube

Offline

Posts: 1,367

Join Date: Jun 2008

Location: CNY

|

01.05.2010, 10:40 PM

Wow I am late on this one... great job!

This should be in Project X ... or maybe I should look at the FLM forum more often! Big thumbz up

My Videos: http://vimeo.com/user2236105/videos |

|

|

|

|

|

(#15)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

01.05.2010, 10:55 PM

Quote:

Thanks man...

|

|

|

|

|

|

| Tags |

| cc 1520 1y, flm carbon fiber chassis, hacker c50 10xl, ofna spider, ue widetrac |

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | Rate This Thread |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode