|

|

|

|

|

(#1)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

09.10.2008, 12:59 AM

Patrick,

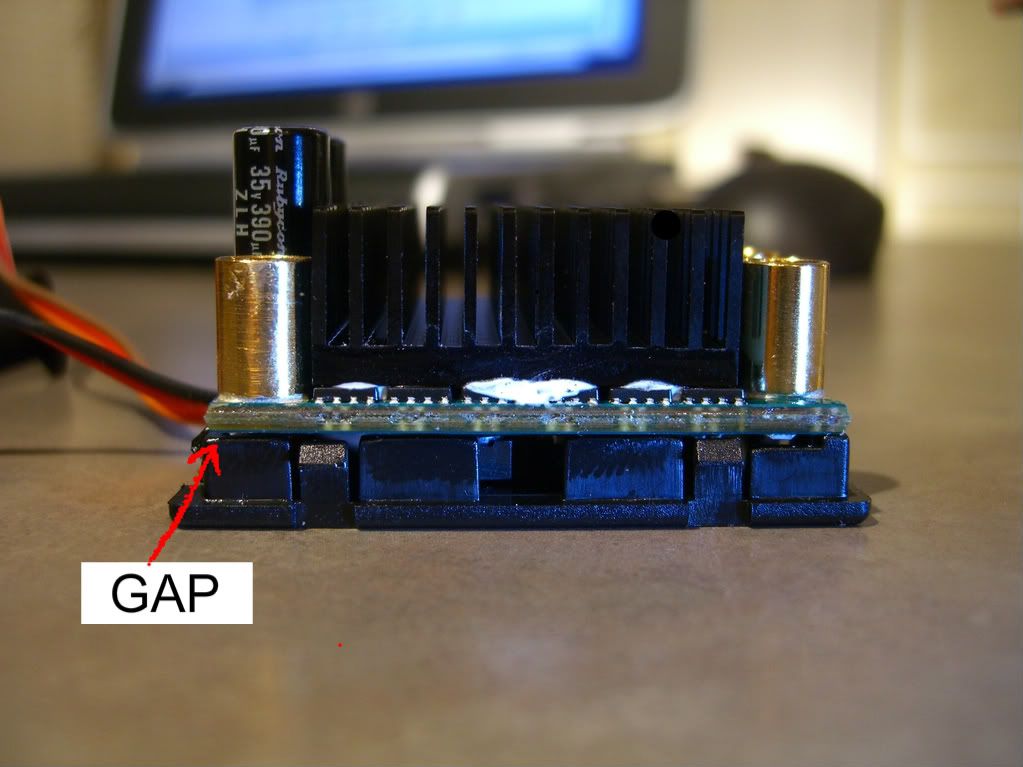

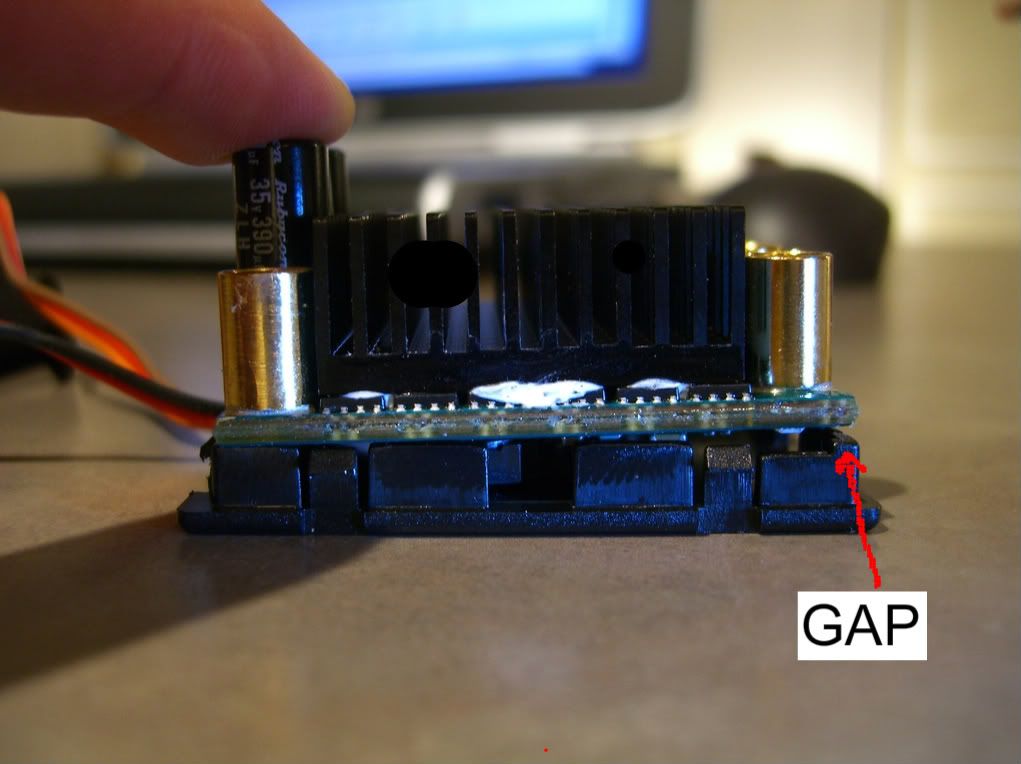

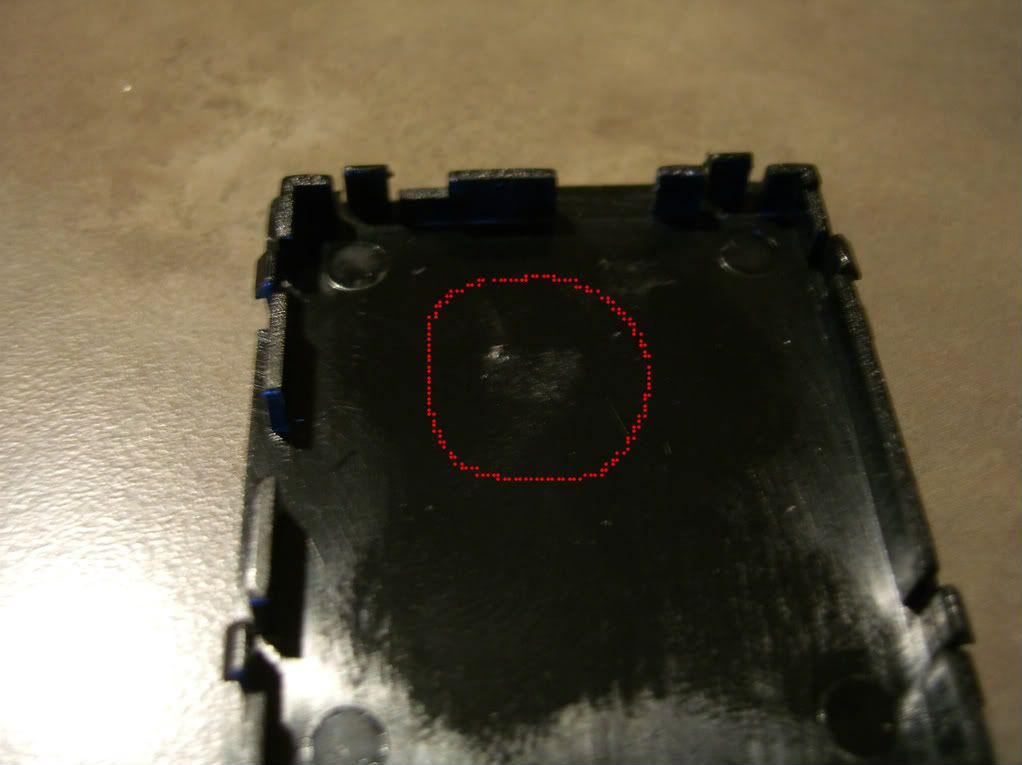

First off. I just want to say that this post is made with purely the best intentions and is intended to be constructive feedback so please donít take this as nit picking or flaming the product because I want nothing more than the BEC issues that seem to still be occurring with to high of a frequency to be fixed once and for all. And rather than sitting around complaining (which is what I have been doing...sorry guys) I figured I would at least try and spend some constructive time feeding back my observations. I make my living as a product development engineer and have been designing/developing consumer products for many years, and yes this means chasing down nightmare little problems that seem impossible to identify. So I can feel what you guys are going through right now. And if there is one thing that I have learned when trying to solve a problem is to start eliminating variables and other minor problems even if they donít seem obviously directly related. Could you guys be chasing what you are thinking is an electrical design or component problem when in fact itís actually a mechanical case design issue causing the component failures? I just want to throw that out there. Here is what I mean and what I am seeing: I have a brand new V2 here that I just took out of the box and I have been looking over this thing for a little while here. One of the problems we have seen a bunch of people post about is the little white fan plug breaking off of the bottom of the board. Itís obvious that you guys over at CC have also identified this problem because in the V2 it appears that a soft foam pad has been put under the plug. Presumably to cushion the plug from contacting the hard case bottom and breaking off. I had the plug break off on my V1 and saw this pad "fix" on the first V2 that I purchased. (That has since gone bad with BEC issues.) I wanted to look at this a little closer before running my 2nd V2. I actually think that the foam pad is making your problem worse. I just pulled the foam pad off of my brand new V2 and set the controller board on top of the base. The board is obviously high centered on the plug. (See the pictures below) I can set the board on the base and the edges of the board donít even contact the edges of the case that are supposed to be supporting the board. All of the pressure is on this one little fan plug component. The plug is soldered onto the board that has the BEC circuits on it that have been giving everyone fits. I'm not an electrical engineer here, but I do know that a cracked circuit board is a good way to make an electronic device stop working, or at least do something unpredictable. This just seems to me to be a MUST FIX item. Even if it isnít causing the problems with the BEC that are happening now. It seems obvious to me that every time I land a jump or hit a bump, the BEC brain board is taking a hit and eventually something is going to give. The plug... or the boardÖ or both? When I measure the height of the board support edges of the case bottom they check 4.8mm tall. When I measure the height of the white plug to the main board that sits on those supports it measures 5.42mm high. This is an obvious interference of at least .6mm. This doesnít even take into account the small amount of flex that the components might see in a jump/bump related impact which could make the interference even worse The pad looks like an attempted quick fix, but it seems to me that the pad just adds mass under the exact point that is creating pressure on the brain board and actually making the problem worse by crating even more constant pressure on it. When the case bottom gets snapped closed it presses on the plug and keeps a constant pressure on that spot. HellÖ It might even be creating a minute fracture the first time the case is closed at the factory and the ones that fail never even had a chance. Could this pressure on the brain board be your problem? I think itís possible. And I have heard a couple of your Techs say that the people that have one go bad usually have more than one go bad. Rather than the components in their electrical system being the cause of the repeated failures in the same setup, could it be the way they are mounting it causing additional stress on this component? For example they are mounting it directly to a hard chassis with no padding. And the guys that are mounting it to something softer or on Velcro or something arenít having the problems. I am going to guess that you guys have already thought about all of this, but I just wanted to throw it out there just in case. Here are links to a few pictures to illustrate what I am talking about.

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#2)

|

|

|

RC-Monster Titanium

Offline

Posts: 1,161

Join Date: Jan 2008

Location: All over Australia.

|

09.10.2008, 01:22 AM

Lol that sounds so familiar. I don't know if you know much about the Xbox 360 and its infamous RROD problem, but MS seem to think the problem is heating, and keep adding heatsinking, but 95% of people (myself included) are able to fix the rrod by replacing their stupid 'x-clamp' heatsink mounting system with something that doesnt flex the motherboard in those critical areas. (ie where the cpu and gpu are mounted).

Apparently (and I'm no expert) the problem was that the flex caused some solder joints to separate. If you take the flex out, they make contact again and voila your back in business. Not saying its the same problem here, but there is an example of a big wealthy company misidentifying a problem - with the extraordinary amount of evidence about the cause off the rrod, MS still don't seem to consider their stupid motherboard flexing clamps a problem. |

|

|

|

|

|

(#3)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.10.2008, 01:42 AM

Very interesting Jhautz. I definately considered this a problem when I first noticed that my v1's internals could be moved inside the case. I clearanced the bottom of the case where the fan plug and round black coil thingy (sorry for the overly technical terms) would contact. I also cut some high desity foam to act as a shock absorbing suspension. I placed a long strip under the solder points for the motor wires, and a small square under each input lead solder point. These tightened up the internals when the case was closed.

I also noticed that the pcb can rub thru the thin fan wires. They are quite a tight fit between the edge of the pcb and the case. I wonder if those wires are having the insulation rubbed off and then shorting together or shorting on the pcb? A dead short there could cause the bec to fail... I need to pull my v1 back apart and see how those small wires are doing. I added some heat shrink to them on the v2, but have not run it much yet... |

|

|

|

|

|

(#4)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

09.16.2008, 10:49 AM

I would still love to hear some thoughts from CC on post #442 in this thread.

http://www.rc-monster.com/forum/show...&postcount=442 to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#5)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

09.16.2008, 10:54 AM

Quote:

|

|

|

|

|

|

|

(#6)

|

||

|

RC-Monster Titanium

Offline

Posts: 1,697

Join Date: Mar 2008

|

09.16.2008, 11:04 AM

Quote:

Patrick President, Principle Engineer Castle Creations |

|

|

|

|

|

|

(#7)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

09.16.2008, 11:12 AM

Thanks Patrick. Good to hear. Will the case change just be a rolling change once the case molds get updated. I know that sometimes it can take quite a while to modify injection molds. Or are you thinking more allong the lines of the case chages allong with other adjustments to other parts of the controller and doing something more like a V3?

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#8)

|

|

|

RC-Monster Mod

Offline

Posts: 6,597

Join Date: Apr 2007

Location: NJ

|

09.16.2008, 11:08 AM

Any objections to DIY versions of this? I was thinking about just cutting the middle out of the bottom of the case to add clearance and glueing an extra piece on to seal... the bottom.

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

09.16.2008, 11:30 AM

+1 to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#12)

|

|

|

I have no idea what's going on

Offline

Posts: 464

Join Date: Jan 2005

Location: UK

|

09.16.2008, 11:31 AM

That's great to hear, Patrick! Should solve a lot of problems

|

|

|

|

|

|

(#13)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 326

Join Date: Feb 2008

Location: Levittown, NY

|

09.16.2008, 11:35 AM

Great work jhautz. There might be something to your observation about the mounting of the MMM too. It'd be interesting to know how those with multiple failures are mounting it. I use dual lock tape which I think is more shock absorbent that regular velcro and my v1 MMM is still going strong.

|

|

|

|

|

|

(#14)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 95

Join Date: Mar 2008

|

09.16.2008, 11:40 AM

OK, you're right, sorry.

|

|

|

|

|

|

(#15)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 463

Join Date: Aug 2005

Location: Malaysia

|

09.16.2008, 11:54 AM

jhautz,

This is great work. I salute u ! Gonna do that to all of mine now. It's things like this that make this forum & members such as yourselves invaluable. Regards, Joe Ling

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Hybrid Mode

Hybrid Mode