|

|

|

(#46)

|

|

|

Guest

Posts: n/a

|

09.13.2011, 01:45 AM

Thank you! I am very much looking forward to driving it now, and hopefully will have some pictures up shortly.

Kieren |

|

|

|

|

|

(#47)

|

|

|

Guest

Posts: n/a

|

09.18.2011, 09:19 PM

Went out for a crawl on Saturday with a couple mates for it's first test drive. It wasn't 100% finished yet, but almost there. I decided to run the BCs and eritex wheels simply because I made my weights to the absolute maximum size possible and they no longer fit VP wheels. I had my old faithful firm inner, soft outer CI foams from my rovers, but I believe they are a bit firm. The other problem I had was the Charlotte's and the BCs would not play nice and I ended up pulling 3 beads (and this is after about 4 goes at mounting the things properly). The slot in the eritex wheels is simply to small to hold any bead properly IMO. So they will be getting lathed shortly.

Now for the good news. Everything pretty well performed faultlessly minus a couple loose bolts and nuts. The mini pullers and wheelspeed to boot and seem to be able to power the rig around most things with no drama's or temperature problems. They will stall in hard digs or binds, but I guess that is to be expected. The shrunk mamba micro's had no problems handling the pullers, and most of the time they barely felt warm. And finally the futaba servo is simply awesome, I was running it on 7.8v and it was only warm, but had enough power to swing the rear end of the rig around no worries. I think I only managed to stall it once, and it was really wedged in. Onto the chassis. The rollover, as expected, was excellent. Thanks to my "brilliant" driving and a bit two much wheelspeed with the pullers I tested this quite thoroughly  The handling was quite good also, for everything from precise slow speed crawling to going flat out up rocks and doing backflips. This chassis will definitely be staying put with very little changes. Hopefully CrawlerX should have them released shortly for everyone to get their hands on them. The handling was quite good also, for everything from precise slow speed crawling to going flat out up rocks and doing backflips. This chassis will definitely be staying put with very little changes. Hopefully CrawlerX should have them released shortly for everyone to get their hands on them. Pictures, well unfortunately I was having to much fun 'testing' to take any pictures or video. So I'll just have to end with a couple I took at the end of the session. You can also see the final design for my knuckle weights.   Kieren |

|

|

|

|

|

(#49)

|

|

|

Guest

Posts: n/a

|

10.01.2011, 06:06 AM

Went for a crawl today at the old faithful spot. I didn't have a chance to make any panels yet. It seemed to crawl quite well, apart from a few minor things that I need to fix. The chassis held up excellently to some decent abuse, along with everything else. Video should be up shortly also.

Kieren |

|

|

|

|

|

(#51)

|

|

|

Guest

Posts: n/a

|

10.03.2011, 04:30 AM

At 8mm I believe I hold the claim to the smallest berg tubes ever produced. Not finished yet, but not to much further

Also on a completely unrelated note my third hand, has suffered a debilitating spinal injury   Kieren |

|

|

|

|

|

(#53)

|

|

|

No Way....

Offline

Posts: 86

Join Date: Nov 2009

Location: France

|

10.04.2011, 06:44 AM

wooo that's a really extrem mod !!!

great work as usual !! great work as usual !!

|

|

|

|

|

|

(#54)

|

|

|

Guest

Posts: n/a

|

10.05.2011, 01:47 AM

Thank you! It still needs finishing, and is quite rough at the moment, but I'm getting there.

Kieren |

|

|

|

|

|

(#55)

|

|

|

Guest

Posts: n/a

|

10.11.2011, 06:49 AM

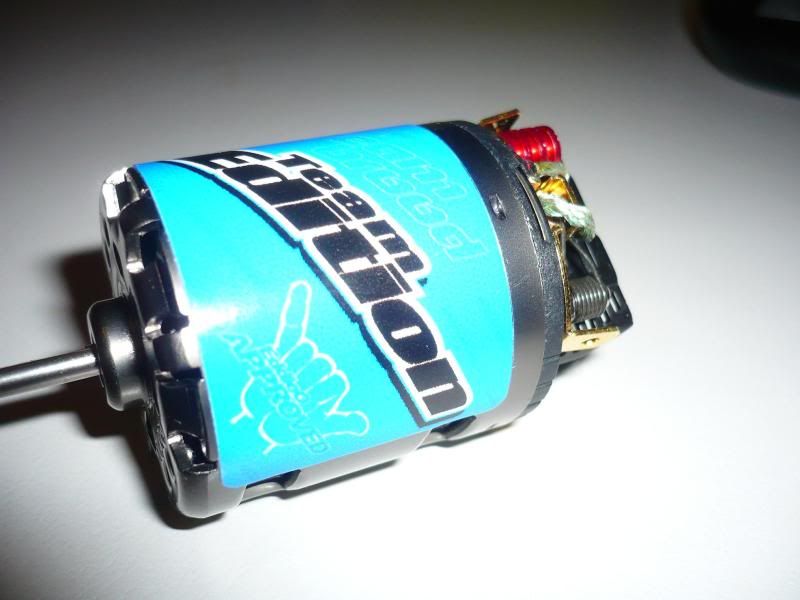

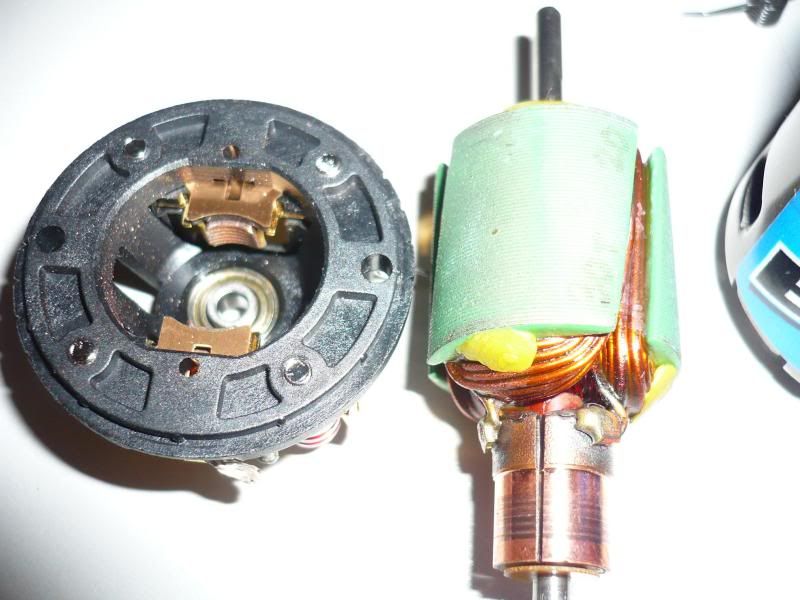

Tubes are finished

Also got some shiny power plants, however these might not go in this rig though. 30t Type S in Kr cans with a few other little extras.    Kieren |

|

|

|

|

|

(#57)

|

|

|

Guest

Posts: n/a

|

11.07.2011, 04:18 AM

Here's a few pictures of the rig from the social on the weekend. Thanks Steve for the pictures :thumbsup:

Very happy with the rig so far, and am proud to say that my Crawler X chassis'd rig was the only rig to make the climb at 1:04 (thanks Jakesy for the video) It might not look like much but it proved to be quite a challenge, no matter what rig you were driving. I'm hoping for a repeat performance now at the state titles if I can make it! Cheers Kieren |

|

|

|

|

|

(#58)

|

|

|

Guest

Posts: n/a

|

12.17.2011, 06:12 AM

Here's some pictures of the very first set of Ras Customs wheels. Granted they aren't completely mine, but they do prove the concept.

I later realised I should have got the weight of the complete wheel, but just as a comparison here is the weights of the original wheel, and the parts that replaced it.   The wheels proved to be very easy to mount, about the same, if not easier than the 'normal' style beadlock. Best part though is it will fit about about 49mm knuckle weights for even more weight under the axle.    Original next to the new internal style  Little bead holding test   Kieren |

|

|

|

|

|

(#59)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 339

Join Date: Aug 2005

Location: Indiana

|

12.17.2011, 09:35 AM

|

|

|

|

(#60)

|

|

|

Guest

Posts: n/a

|

12.17.2011, 11:25 PM

It's been working great, hands down the best servo I've ever had anything to do with. No slop as far as I can tell, from what the team drivers for futaba, in the rock crawling segment anyway, have said is that the brushless motor seems to have a bit more 'give' than a normal brushed/coreless motor and that seems to help the gear life. Unless you like crashing into things I wouldn't worry about the gears too much, I've had it wedged between rocks so hard it stalls and it's still keeps going. Only thing is it does get a little warm after you wedge it a couple times. No idea on the material strength of the gears compared to hitec, but IMO it's a far superior servo to anything hitec has to offer. Just feels smoother, quicker and more powerful, compared to 7950s and 7980s.

Kieren |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode