|

|

|

(#61)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.23.2009, 08:16 AM

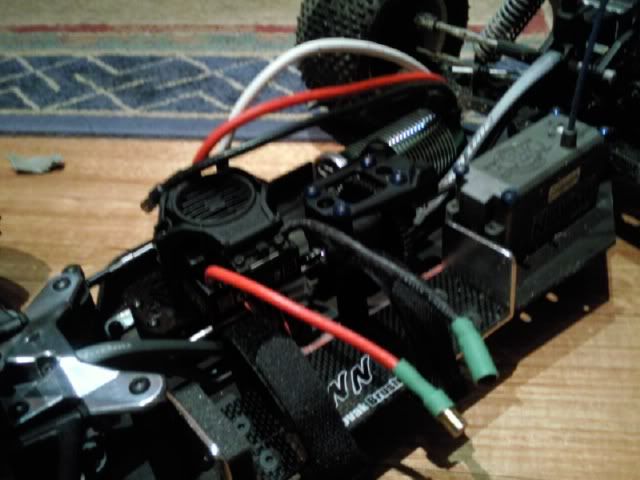

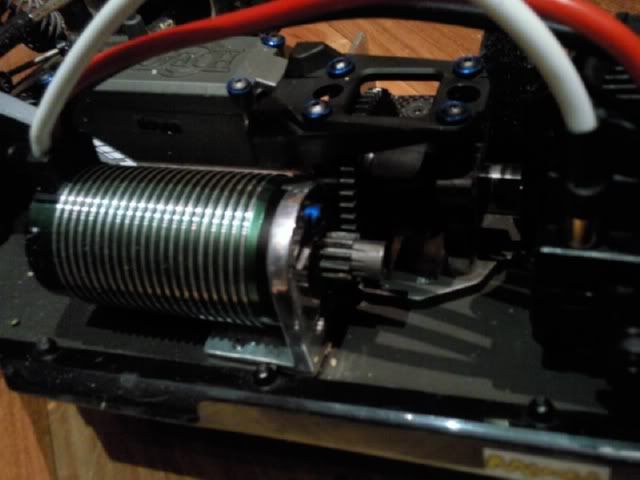

My MMM arrived today :) Need to fix the motor mount AGAIN or just make another one...

Pictures aren't top quality but they will do for the time being :)       Yes i know the motor wires are being stretched but i have unplugged them and i'm fixing that tomorrow. Any one know what plastic spurs will fit? |

|

|

|

|

|

(#62)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

09.23.2009, 09:54 AM

That looks nice. do you have plans to make the battery tray a box, rather than a slot of sorts? Because if your velcro lets go during a run that'd not be good...

|

|

|

|

(#64)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.24.2009, 03:44 AM

Yes i may make a battery box, but i;m very happy with the velcro im using as its very strong.

Novak sticker in on the because im using novak pinions. $22 for 3 pinions!! Just took it for a run and all i can say is WOW! This thing has so much power its just not funny! F/R balance seems pretty good on the road, maybe just a tad nose heavy. |

|

|

|

|

|

(#65)

|

|

|

Guest

Posts: n/a

|

09.24.2009, 05:28 AM

yea you are right the novak pinions are about the best thing they make for 1/8 scale! lol

|

|

|

|

|

|

(#66)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.24.2009, 08:57 AM

I seem to have a meshing problem so i need to make a whole new motor mount design....AGAIN!!

The RCM mount looks good right about now... |

|

|

|

|

|

(#67)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

09.24.2009, 09:38 AM

YES! RCM mount FTW!

|

|

|

|

(#68)

|

||

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

09.24.2009, 09:42 AM

Quote:

but, a new and solid one is not a problem. just make it a bit "wider", so the mount reaches to the plastic mount of the center diff. you can use the mounting holes of the mechanic breaks, and with two screws the mount is also connected with the diff. like that, meshing is impossible. w. some fresh saw blades, driller etc. it's no big deal at all, but cheap and solid. |

|

|

|

|

|

|

(#69)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.25.2009, 03:14 AM

The problem i'm having is that the motor is sliding away from the spur gear no matter how tight i do the two screws up. I have come up with a way of using two long grub screws. I will draw up a picture of what i mean. (i cant explain things very well).

|

|

|

|

|

|

(#70)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

09.25.2009, 04:17 AM

hmm, i think I know what you mean, I had the same problem.

first you should use some (light) loctite bolt lock (not the hardcore stuff!!), and some proper washers. with the washers you have a larger surface for the bolts/screws. I know there is only little space for washers, but it works. I think at the moment you have only very little survace with that bolt. further I think the polished surface causes that problem, too. I don't think that you need to make a totally new mount. but later you probably could add a metal plate (just inbetween motor an the mount, with the same holes for srews and motor-axle), that braces the mount to the center-diff. like that you keep the acutal mount, and just have to make new mounting holes in the chassis. I don't know how to explain that, a bit like that:   hth florian |

|

|

|

|

|

(#71)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.25.2009, 07:08 AM

Pictures don't work.

I have solved the problem by using a mount i previously made. It's a beefy version of the RCM mount. Just need to fix a small problem with the mount and clean it up. I also have the problem with the pinion coming off the shaft all the time. I have put loctite on the grub screw and will test it tomorrow. Any other ideas if loctite doesn't work? |

|

|

|

|

|

(#72)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 354

Join Date: Sep 2008

Location: Hamburg, Germany

|

09.25.2009, 07:16 AM

maybe the mount is not parallel/in line to the diff, so it pulls the pinion off.

loctite should help. is the flat area on the shaft still ok? |

|

|

|

|

|

(#73)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.25.2009, 07:31 AM

Yeah flat area is fine....

|

|

|

|

|

|

(#74)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 73

Join Date: Jun 2009

|

09.26.2009, 08:21 AM

I had a successful day of running the Hyper ST. Pinion hasn't left the shaft all day.

A problem i will try to sort out tomorrow is getting the wheels balanced so my truggy isn't getting shaken to bits. Also my 30c 5s Turnigy lipo is performing very well and doesn't get too warm. Takes 128mins to fully charge. Loads of power! |

|

|

|

|

|

(#75)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 93

Join Date: Aug 2009

Location: PERTH,WESTERN AUSTRALIA

|

09.26.2009, 08:27 AM

hey mate ,great work ,good to see you got it all sorted

,when will we see a vid.... ,when will we see a vid....

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode