|

|

|

(#61)

|

|

|

HOOH HUAH HOOH! Aww Baby!

Offline

Posts: 868

Join Date: Oct 2007

Location: olyWA

|

09.09.2011, 10:02 AM

I can't believe that thing only handles 8s...wow. I'll try my rx8 on 6s I think. I'll have to give Tekin a call to see if the rx8 can unofficially handle anything above 6s but it's still a lot of power. Have you considered using a rx8 in the meantime?

|

|

|

|

|

|

(#62)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.09.2011, 10:14 AM

Nah I'm a Castle fanboy

|

|

|

|

|

|

(#63)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.14.2011, 09:02 AM

Finally got around to fitting the hub on! Hub on the XL axle with pin through both.

O-ring on the hub to hold pin in place and then with the wheel mounted.   Gave the machinist the go ahead on producing more so I'm getting anxious to see a full set in use! |

|

|

|

|

|

(#64)

|

|

|

RC-Monster Aluminum

Offline

Posts: 800

Join Date: Oct 2009

|

09.14.2011, 09:23 AM

Looks very clean. This is what HPI should have designed, even for 17mm wheels, in the first place!

|

|

|

|

|

|

(#65)

|

|

|

Guest

Posts: n/a

|

09.15.2011, 11:32 PM

Looks very impressive to say the least. Well done. How hard was the HPI stub axle to drill? Did you have to use a special bit to do the job? Last question. Would you consider making the same thing but in 17mm version for us that are still running 1/8th size? Would be very nice if you did it with similar off set as the stock XL setup has.

|

|

|

|

|

|

(#66)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.16.2011, 08:27 AM

Used a carbide tip for the hole in the axle to play it safe.

Funny you ask, I'm working with someone on a 17mm version. He's wanting it to work on box the X and XL axle though so that's proving to be a little challenging. XL axle is easy, I'd just copy what I did here basically. |

|

|

|

|

|

(#67)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

09.17.2011, 02:03 PM

I've glanced at this project now and again - but haven't commented yet. I just looked through the whole thing again and all I can say is very nice work. You're making me think more and more about getting back to my on-hold large scale project!

-brian |

|

|

|

|

|

(#68)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.19.2011, 09:14 AM

DO IT! Got a build thread for it?

|

|

|

|

|

|

(#69)

|

|

|

RC-Monster Aluminum

Offline

Posts: 768

Join Date: Jul 2009

Location: NJ

|

09.19.2011, 09:33 AM

|

|

|

|

|

|

(#70)

|

|

|

Guest

Posts: n/a

|

09.20.2011, 06:07 AM

You really have to get back into that project Brian. I was really enjoying watching everything get hand made. Would really like to see it finished.

|

|

|

|

|

|

(#71)

|

||

|

Guest

Posts: n/a

|

09.20.2011, 06:19 AM

Quote:

Best thing about this is that the offset stay the same. Not sure how well it would work on Flux or non XL axles though. Still I would like to see something purpose made like you did for the 24mm ones. |

|

|

|

|

|

|

(#72)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.20.2011, 08:22 AM

Not much progress made on the 17mm hubs at this point. Still doing some sketches. We've thought about doing exactly what you did but we're leary about the small amount of material left behind the pin? There's a few ideas we're exploring. We're trying to make something that will work on XL and non XL axles as well.

|

|

|

|

|

|

(#73)

|

|

|

KillaHurtz

Offline

Posts: 2,958

Join Date: Apr 2006

Location: Bucks Co, PA

|

09.20.2011, 09:33 AM

Excellent part and design. :)

|

|

|

|

|

|

(#74)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 209

Join Date: Sep 2008

|

09.20.2011, 11:49 PM

Well the test run was disappointing..... Truck is still in one piece so I can't complain too much.

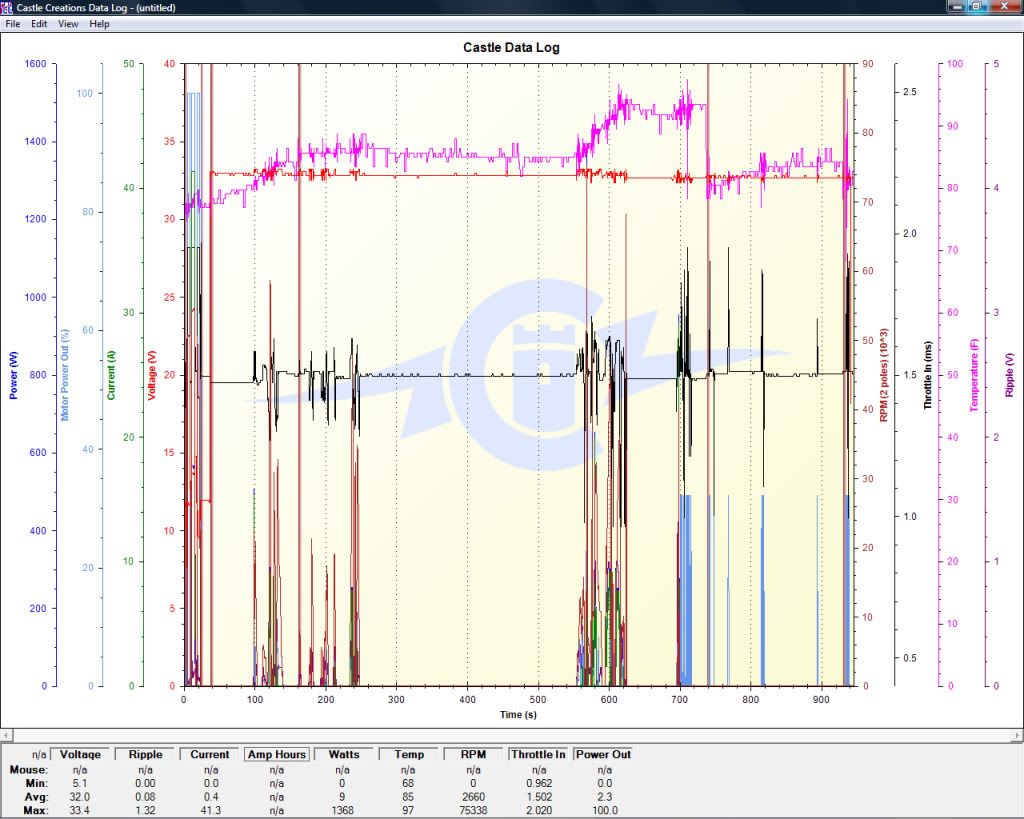

http://www.youtube.com/watch?v=Puf7O4uHqj8 And some data even though it's pointless...  What do you guys think? ESC Failure? I sure hope it's not the motor! Why are the "max" ratings on the data logging really strange? 75k RPM!? |

|

|

|

|

|

(#75)

|

|

|

Guest

Posts: n/a

|

09.21.2011, 05:45 AM

I sure hope it's not the motor. Those 1717 motors aren't exactly everywhere. 75,000rpm????? Highly unlikely but who knows. Did you take the motor out and try to turn it by hand? Should also take the front of the motor off and have a look at the state of the rotor.

IMO the slipper on the Savage is way too ineffective even on a normal Flux. Same thing as you have found out. Either it screams in agony slipping or you have to lock it to the point where you might as well not have one. Have a look at the slipper eliminator from Alza racing. Edit; Just had a closer look at the graph. It states (to me at least) that it is the readout for a 2 pole motor. The 1717 is a 4 pole (ahhhh duhh). Anyway that 75,000rpm can be halved. I think you only hit 35-37K. I hope I am correct here. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode