|

|

|

(#121)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,436

Join Date: Nov 2005

Location: Edmonds WA

|

05.16.2010, 01:52 PM

Not trying to derail this thread, but I have a quesiton on CF cutting. I have never seen anyone speaking positive or negative on waterjetting of CF. Do you have any knowledge on this? Or laser cutting of it (might not be able to get a laser strong enough).

|

|

|

|

|

|

(#122)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.16.2010, 02:06 PM

Quote:

They are conversations on these topics below: Laser cut carbon fiber? Waterjet cutting carbon fiber |

|

|

|

|

|

|

(#123)

|

||

|

UE Supermaxx Addict!

Offline

Posts: 1,006

Join Date: Feb 2009

Location: Gadsden, Alabama

|

05.16.2010, 02:25 PM

Quote:

Check out the links that ANGRY-ALIEN posted above. › PM ME IF YOU HAVE THE BELOW: › VBS, CVDs, GM Single-Speed, OTB, Ultramaxxed, Super6, Strobe, Sprong, CNR Brake, UE Hex, DUH Towers, Predator, Blackbird, GA Blue Screws, HCR F/R Skids & Mutant |

|

|

Widetracs |

|

|

(#124)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

Widetracs -

05.17.2010, 12:31 PM

Hmmm... it's been some time since my last update on the build... I have been trying to work out designs for a new motor/cd mount to facility my 1520 beast and it has delayed the entire project,

but for now I'll make a small update... Although I've had great success with the proline control arms, I recently decided to employ a set of UE Widetrac arms... it's been a long time dream to own a set of UE suspension arms (I still think UE parts though well designed and machined are little overpriced) and when I saw this set on ebay going for a 'reasonable' price, I didn't want to pass on the opportunity. They were pre-owned and well used... The the surface was well polished, but with use tiny holes were developed all over the rear arms... the lower undersides rear/front also suffered (did I mention these were well used?)... there was some evidence of the arms making contact with the output cups... So some clean up was required before assemble and installation. I started the clean up with some wet 400 grip sand paper to rid the surface of most of the holes and scratch marks... then I graduated to a 600 grit to smooth things out. Now, I'm not a big fan of super polished aluminum... So I used some steel whool and rubbed the arms in one direction and finished it with Scotch Brite to achieve a 'brushed aluminum' effect... I think they turned out quite well... see pics below.  UE Widetrac Control Arms  The surface finish after sanding and good Scotch Brite rub  This pic illustrates the result of the arm making contact with an output cup  UE Widetrac Control Arms, UE Monoblock, FLM Bulks and UE Knucklehead shock towers  More update coming... 'Stay tuned' Alien |

|

|

|

|

|

(#125)

|

|

|

UE Supermaxx Addict!

Offline

Posts: 1,006

Join Date: Feb 2009

Location: Gadsden, Alabama

|

05.17.2010, 12:42 PM

Looking good...UE Widetracks, UE Monoblock, UE Knucklehead Shock Tower Kit, UE Ultralites (with 6 ot 8-spiders), HCR Titanium Skids, Diemaker dave Wing-Mount, FLM Bulkheads...nice!

› PM ME IF YOU HAVE THE BELOW: › VBS, CVDs, GM Single-Speed, OTB, Ultramaxxed, Super6, Strobe, Sprong, CNR Brake, UE Hex, DUH Towers, Predator, Blackbird, GA Blue Screws, HCR F/R Skids & Mutant |

|

|

|

(#126)

|

|

|

UE Supermaxx Addict!

Offline

Posts: 1,006

Join Date: Feb 2009

Location: Gadsden, Alabama

|

05.17.2010, 12:44 PM

Oh, if you decide you want the radically changed suspension geometry of the UE EXT Suspension (handles MUCH better), I have a complete kit, so just let me know...

› PM ME IF YOU HAVE THE BELOW: › VBS, CVDs, GM Single-Speed, OTB, Ultramaxxed, Super6, Strobe, Sprong, CNR Brake, UE Hex, DUH Towers, Predator, Blackbird, GA Blue Screws, HCR F/R Skids & Mutant |

|

|

|

(#127)

|

|||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.17.2010, 12:56 PM

Quote:

Thanks man  , but the diffs are actually Hot Bodies Lightnings... lots more work left before I'm satisfied. , but the diffs are actually Hot Bodies Lightnings... lots more work left before I'm satisfied.Quote:

So since they'll be used for mostly bashing and very light racing, the Widetracs will do for now... Alien |

||

|

|

|

|

|

(#128)

|

|

|

Second place is the first loser!

Offline

Posts: 899

Join Date: Sep 2008

Location: Utah

|

05.24.2010, 01:05 AM

great looking build. cant wait to see it all together. i have done a lot of builds with carbon and had to learn the same things. the CNC left burrs that i had to sand off. and the best way to make countersinks is to use a dremel stone/sanding bit and grind at an angle and move around in a circular motion. obviously you already figured this out. i have tried to get others out there to tell me the best way to cut carbon but they are not willing to share. i have tried lazer, CNC, and water jet and so far the best cuts still come from my dremel tool.

Losi Ten-T SCT conversion Neu 1512 1y |

|

|

|

|

|

(#129)

|

|

|

UE Supermaxx Addict!

Offline

Posts: 1,006

Join Date: Feb 2009

Location: Gadsden, Alabama

|

05.24.2010, 01:31 AM

The tool isn't as important as the bit when cutting/milling carbon-fiber. You need high-quality carbide bits if you want perfect results. My carbide countersink makes perfect countersunk holes in carbon-fiber, and it has already made hundreds...in carbon-fiber, 6061 & 7075 aluminum, stainless-steel, and even steel.

› PM ME IF YOU HAVE THE BELOW: › VBS, CVDs, GM Single-Speed, OTB, Ultramaxxed, Super6, Strobe, Sprong, CNR Brake, UE Hex, DUH Towers, Predator, Blackbird, GA Blue Screws, HCR F/R Skids & Mutant |

|

|

|

(#130)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.24.2010, 01:31 AM

Quote:

Thanks man... I have some photo updates coming... in regards to cutting carbon on a CNC... I strongly believe if the operators of these machines are using higher RPMs on the cutting tools with a slower X/Y movement over the material, the cuts might be a little cleaner (thus being free of burs)... Yah... I do prefer using a grinding tool for countersinks... Alien |

|

|

|

|

|

|

(#131)

|

||

|

Second place is the first loser!

Offline

Posts: 899

Join Date: Sep 2008

Location: Utah

|

05.24.2010, 06:18 AM

Quote:

Losi Ten-T SCT conversion Neu 1512 1y |

|

|

|

|

|

|

(#132)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

05.25.2010, 06:07 AM

I've seen that 'up spiral' bits leave a perfect finish on lexan/ acrylic, not sure how they would work for CF though.

|

|

|

|

|

|

(#133)

|

||

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.25.2010, 10:39 AM

Quote:

"Milling cutter for carbon fiber"  "Solid Carbide Carbon Graphite Cutter" Base on the designs above, I think you will have to look for a tool that really grinds away the material to leave a clean 'cut'... I am also assuming that these tools are spon at a high rate too. If I find any more, I will post them.  Alien |

|

|

|

|

|

|

(#134)

|

|

|

UE Supermaxx Addict!

Offline

Posts: 1,006

Join Date: Feb 2009

Location: Gadsden, Alabama

|

05.25.2010, 11:35 AM

Yep, those are the new cross-cut multi-flute end-mills made specifically for different grades of CF, and they are for high-speed mills. They will work in lower-speed mills, such as home drill-presses and the like if you go slow, but will work great in high-speed routers if you don't have a true mill or CNC mill!

› PM ME IF YOU HAVE THE BELOW: › VBS, CVDs, GM Single-Speed, OTB, Ultramaxxed, Super6, Strobe, Sprong, CNR Brake, UE Hex, DUH Towers, Predator, Blackbird, GA Blue Screws, HCR F/R Skids & Mutant |

|

|

|

(#135)

|

|

|

RC-Monster Aluminum

Offline

Posts: 809

Join Date: Jan 2008

Location: JAMAICA

|

05.25.2010, 10:54 PM

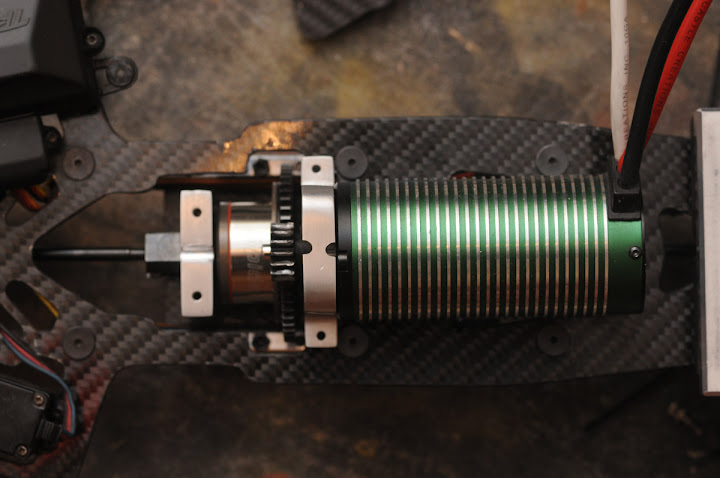

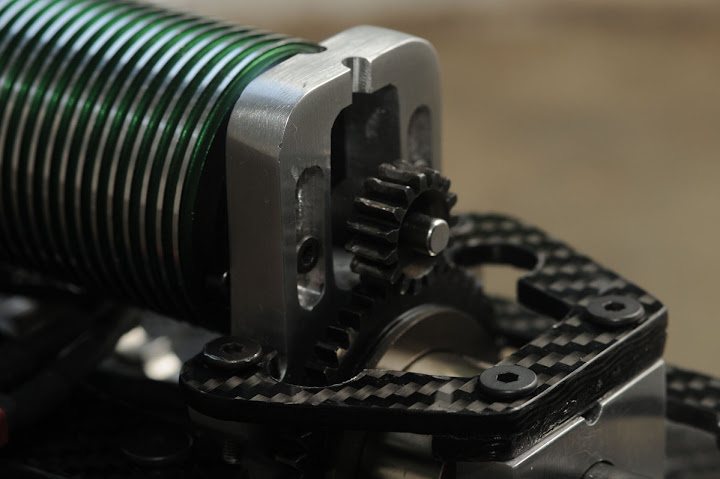

Continuing with my updates on the rebuild... I have manged to finish my 'homemade' CD/motor mount... It was my first attempt on milling with an actual mill... a little different

from sticking a milling bit in dremel and hacking away on the material... the finish wasn't perfect, but i'm sure to get more function than form with this mount... so finished the surface with a file, sandpaper and scotch brite. got it all bolted up together and feels great... it's a lot more sturdy than my previous attempts... there is no play at all from the mount... photos of the mount layout below. I also got the suspension all mounted up... I love the look of these Widetracs... feels a lot smother that the prolines and offers a few more setup options... see the photos below.  UE Widetrac Control Arms, FLM Bulks, UE Super Shocks and UE Knucklehead shock towers   My new homemade CD/Motor mount with a OFNA Spider center diff and CC 1520 attached  Oops!! I accidentally cut the grub screw access slot on the wrong side   Cutting the upper plate for the CD with a dremel cutoff wheel   Upper plate finished and mount mounted  more to come... |

|

|

|

|

| Tags |

| cc 1520 1y, flm carbon fiber chassis, hacker c50 10xl, ofna spider, ue widetrac |

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode