|

|

|

(#31)

|

|

|

Guest

Posts: n/a

|

12.06.2007, 07:47 PM

I want to see some pics!

Im curious to see how you do your motor mount |

|

|

|

|

|

(#32)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.06.2007, 08:00 PM

Unfortunately you'll have to wait a couple hours, when I get home from school. But in case you want a visual, the motor mount is a 1 1/2" wide x 4" long x 1/4" thick piece of polycarbonate (clear) bent to a 90 deg. angle, and the bottom leg sits below the motor.

|

|

|

|

|

|

(#34)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.09.2007, 02:28 AM

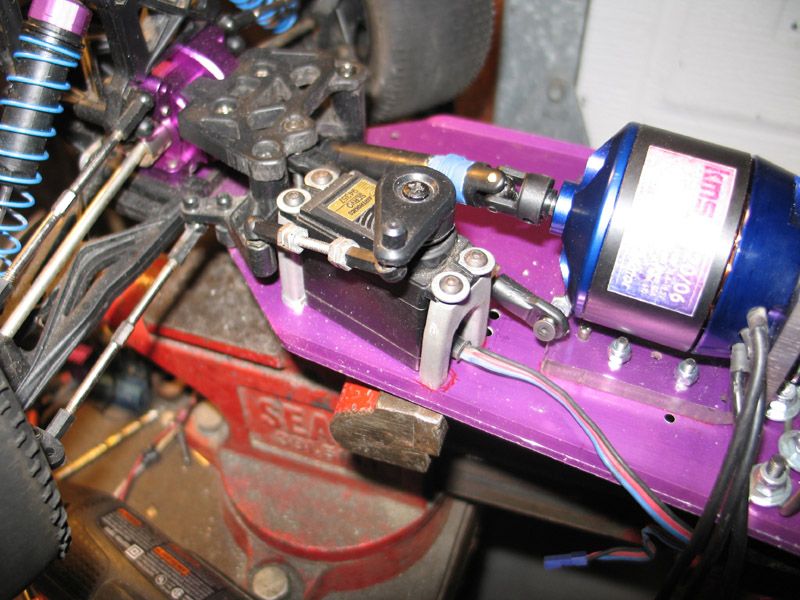

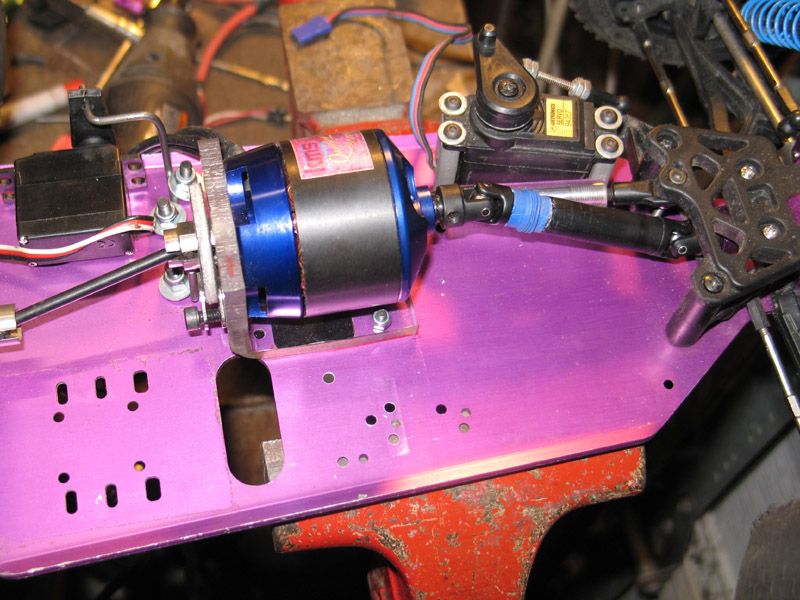

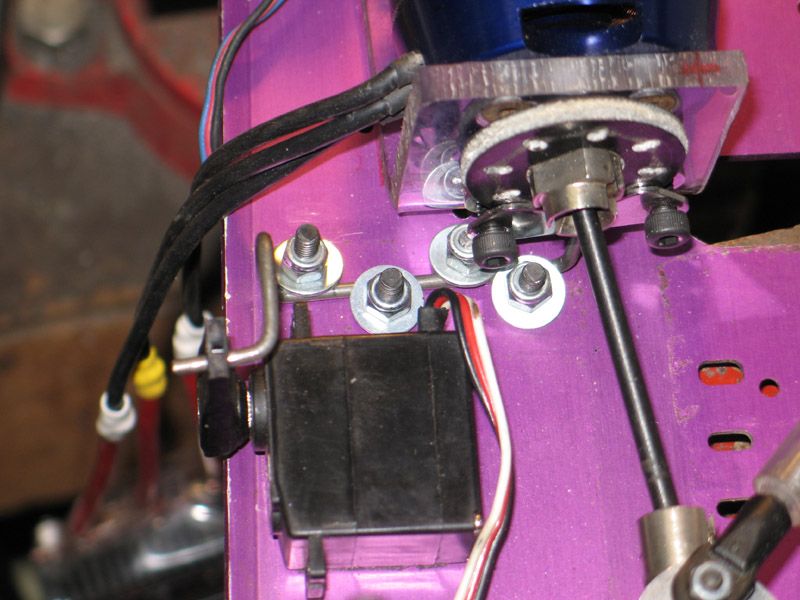

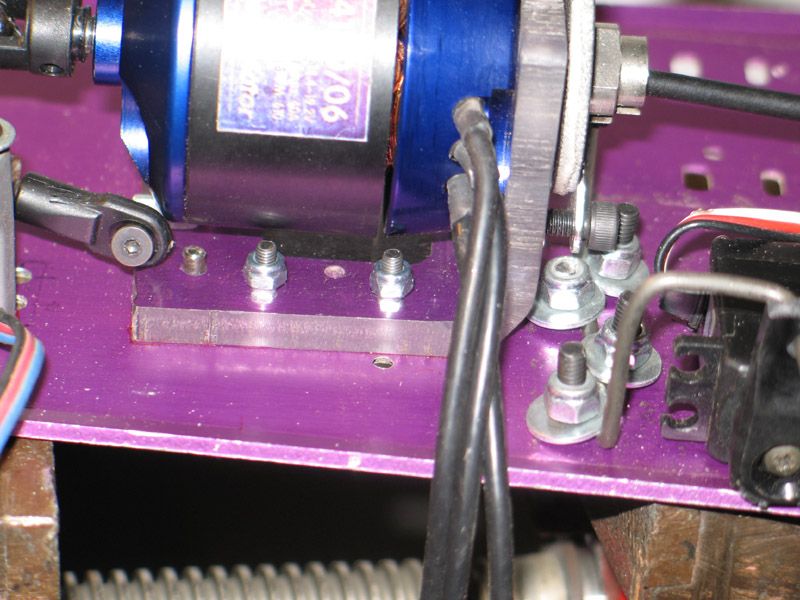

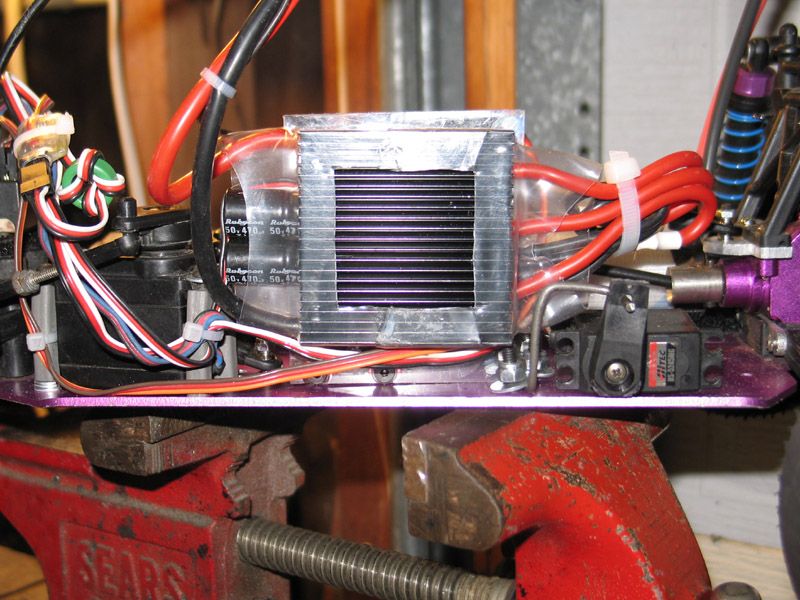

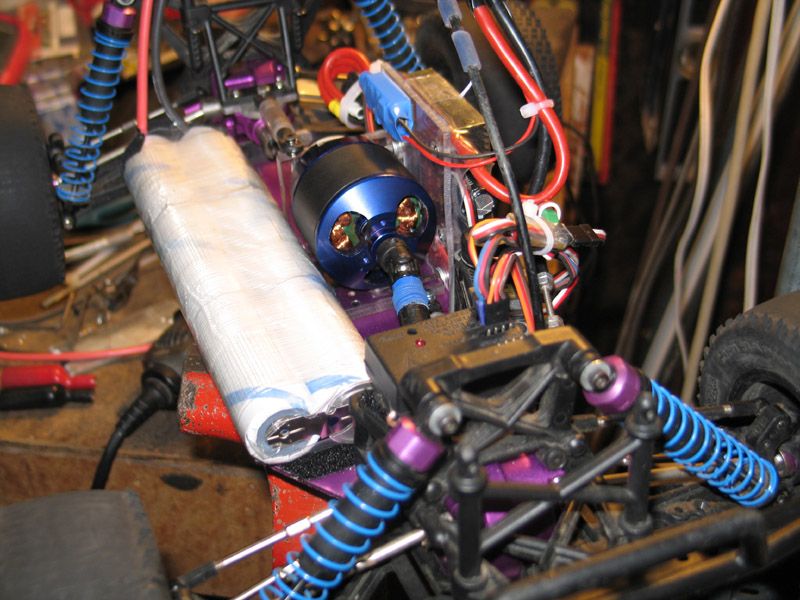

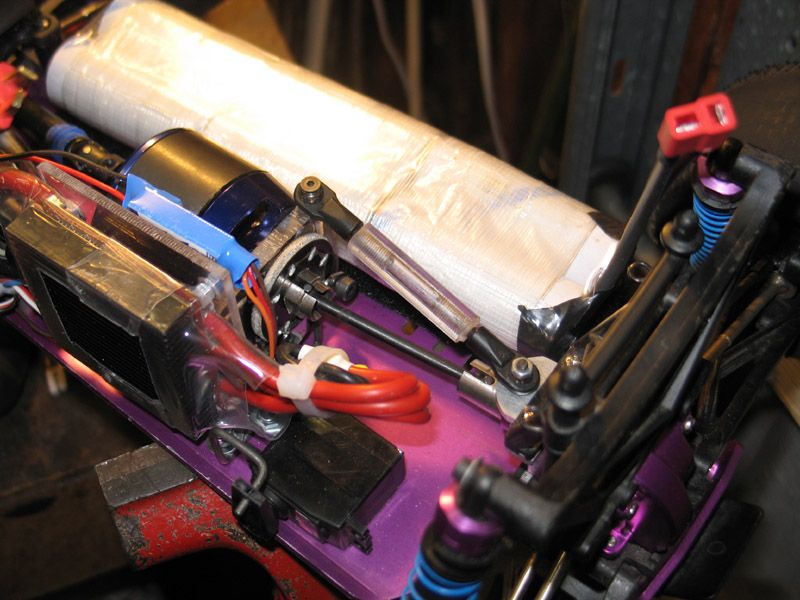

Woops, it's been a couple days... But the truck is now "finished" (with quotes because we are never actually done with them).

The servo mount is made from T-Maxx throttle servo mounts that were put in a vice to be narrowed with the help of a heat gun, were then cut down to let the servo sit lower, and were drilled.  Motor mount is 1/4" thick polycarbonate bent to a 90 deg. angle with a heat gun, and drilled to accept the motor and the screws to hold it to the chassis:  The brake setup uses the pads/rotor from the MT2, and an (obviously) custom actuator bar bent from steel music wire, that is held to the chassis with screws  . The mini brake servo is a Hitec 5245mg that was left over from when I put in a standard size servo onto the chassis for my CRT.5. That servo is simply servo-taped to the chassis. . The mini brake servo is a Hitec 5245mg that was left over from when I put in a standard size servo onto the chassis for my CRT.5. That servo is simply servo-taped to the chassis.  The brakes are decently strong, certainly nothing too impressive, though Next up was ESC mounting. Quite a pain, considering the size...  But I figured it out, and managed to incorporate the ESC mount into a brace for the motor mount, that will keep the mount from flexing (from the weight of the motor), where the flex could cause the spinning can of the motor to hit the motor mount. The brace/ESC mount mounts to the motor mount by 4 screws, and 3 screws hold the ESC to it.  Then I had to figure out a battery solution. I had a virgin Dewalt 36V pack that was out of the casing. I knew I wanted a shotgun-style pack (like the NiMh stick packs) because that's what would fit on the chassis. What I did was simply bend the tabs that were already between the cells, to give me a VERY simple 6s1p pack, that took all of maybe 10mins to make, with the only soldering being to attach wires and a Deans connector to it. It is secured to the chassis with industrial strength Velcro along the whole underside of the battery.  With the 4 remaining cells I plan on making the same style of pack, but shorter. The result will be 10s1p A123... Can you say POWER? And here's another overall view:  You can see the custom rear brace, and there's a similar brace in the front that's kinda hidden, that attaches the front upper deck to the chassis plate. |

|

|

|

|

|

(#35)

|

|

|

Guest

Posts: n/a

|

12.09.2007, 02:44 AM

Nice!

Really tight for room, lol I like your breaks   Have you ran it? |

|

|

|

|

|

(#36)

|

|

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.09.2007, 02:44 AM

Today I maidened the truck. Initial thoughts were, "wow, this truck takes off fast". The minimum throttle position results in a pretty high speed, but that's not surprising considering the cheap airplane ESC and the direct-drive setup.

As others have found, outrunner startup is odd. If I GRAB full throttle, there will most likely be harsh cogging (and some interesting musical tones). If I grab some throttle, the truck might move a foot smoothly, and then encounter some cogging, only to take off. It doesn't happen all the time, especially more recently since I'm learning how the throttle wants to be worked, but when I do get past this "post first-foot-cogging" point the truck accelerates like no other... Too fast, in fact. Traction becomes a HUGE issue with acceleration like that. After work I pushed the truck pretty hard on asphault with the tires shown (worn down HPI Dirt Bonz). The motor and ESC had no problems taking the abuse. Only problem I noticed, is that the ESC has a bit of a lag to it when getting the motor RPM up to the point it should be at relative to the trigger position. That is really only an issue when I'm trying to do drifting (be it on asphault or a waxed floor). Unfortunately the truck doesn't seem to like this much power. Previously with a Feigao 9L and 4s2p A123 it had problems with the diffs clicking (with the hardened diffs), yet inside the diff housings there was nothing but a little grease. That's when I went to aluminum diff housings. During the pavement run, the rear diff actually went out, and since a new ring/pinion costs $32, I'm hoping it's just the internal diff gears. |

|

|

|

|

|

(#37)

|

|

|

Guest

Posts: n/a

|

12.09.2007, 02:54 AM

I wonder if there is a speedo that wont cogg..... cogging REALLY bugs me, but I would like to do a direct drive car, its not near the top, but would def be a fun project

Sounds like she runs good though... Whens the vid? =P |

|

|

|

|

|

(#38)

|

||

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.09.2007, 03:00 AM

Quote:

Uhhhh.... I guess it will have to wait for the rain to stop. |

|

|

|

|

|

|

(#39)

|

|

|

Guest

Posts: n/a

|

12.09.2007, 03:03 AM

Yeah, I have no clue what I would do direct to diff in... but that will be cool when the cogging is gone, or close to gone

Darn rain! |

|

|

|

|

|

(#40)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

12.09.2007, 01:46 PM

Nice looking conversion Metalman! You were right, the MT2 chassis is quite a bit narrower than the old redcat that I am using. You still managed to get everything in there, and I really like your mech brake setup, quite innovative!

I am suprised that the esc is having problems, what kinds of adjustment does it offer? If it has some sort of startup power or torque adjustment, set it to high, or full. Since you are using mechanical brakes and high voltage you could try a phoenix 45 hv esc. The castle startup should be better. |

|

|

|

Mt2/Crt.5 |

|

|

(#41)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 214

Join Date: Dec 2007

Location: Ontario, Canada

|

Mt2/Crt.5 -

12.09.2007, 02:27 PM

It was only after I sold my MT2 and paid 3 times as much for a CRT.5 that I realized just how similar they are. It seems like the CRT would be better if it was a little longer and guess what, the MT2 is. I bought the MT2 because I had blown up the diffs on several 1/10 cars with BL. I thought the MT2 diffs probably would hold up. I moved on to my E-Maxx without doing the conversion. The CRT is more refined and the center diff makes it much more driveable. So now I wonder how I could incorporate a center diff into a direct drive build. It might also provide the key to reducing driveline shock?

|

|

|

|

|

|

(#42)

|

||||

|

RC-Monster Mod

Offline

Posts: 5,297

Join Date: Mar 2005

Location: SoCal

|

12.09.2007, 05:17 PM

Quote:

Quote:

The HV-45 would be nice, and would definitely start better (my HV-110 starts the KB45 in my Savage very nicely), but it's still $35 more than this OEM RC ESC. Quote:

It would be interesting to incorporate a center diff into an outrunner motor. Based on how we are currently doing this "direct drive to diff" stuff, there doesn't seem to be a way. However, a oneway on the front driveshaft would be helpful, as it would allow us to have rear-only braking, which can put the trucks sideways into turns. There has also been another way to reduce stress on the driveline that we have only briefly discussed - adding two slipper clutch setups, with each one between the outrunner motor and the diffs. I've put some thought into it, but am very far from actually making anything of that type. |

|||

|

|

|

|

|

(#43)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.09.2007, 06:33 PM

Quote:

You did a great job. It does sound like you got yourself a good taste of outrunner power. I didn't know there was such a thing as too fast?  Outrunner's do have a different feel to them, but the acceleration can be blistering. Outrunner's do have a different feel to them, but the acceleration can be blistering.The power to weight ratio of the outrunner motors are pretty impressive IMO. They definately make for numerous new possibilities. Bullet proof diffs are a must, especially the rear one. This is why I chose the Revo, knowing that Mike could set me up with some REALLY tough diffs. When you get your diff replaced/rebuilt, try playing with the timing some. Timing can really make a difference. |

|

|

|

|

|

|

(#44)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

12.09.2007, 06:36 PM

Quote:

Be thinking ahead of time about upgrading your diffs. The rear one won't last long. |

|

|

|

|

|

|

(#45)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 405

Join Date: Jun 2007

|

12.09.2007, 08:24 PM

MetalMan, that is a really cool project. Thanks for sharing the build. Is there a smaller outrunner motor that would work good with a MambaMax and fit in a CRT.5? I really like my CRT.5, but I wish it was lighter and had more room on the chassis for batts. Does removing the center diff make driving on a track a lot harder? Is the direct drive system more for bashing?

Thanks again! E-CRT.5 Stock - Sidewinder/4600/2s, buggy tires E-8ight - Tekin RX8 2000kv/4S E-8ight T- Tekin RX8 1700kv/5S |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode