|

|

|

(#16)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

03.11.2008, 04:05 AM

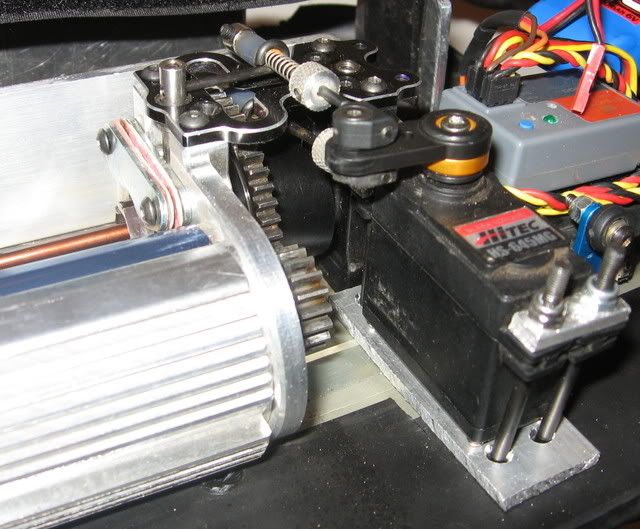

jhautz, that is one clean setup. I really like the innovative linkage you got there to run the mini servo inboard. Nice fabrication too. Yeah I was wondering what that extra battery was before I read your caption.

|

|

|

|

|

|

(#17)

|

|

|

Guest

Posts: n/a

|

03.11.2008, 01:53 PM

Hey, jhautz, what kind of buggy is that in the pictures? Just wondering, thinking about doing a brushless buggy, haven't decided which one to get though.

|

|

|

|

|

|

(#18)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.11.2008, 02:14 PM

Thanks shark.

Fast5 - Its an Xray XB8EC. You can grab lightly used ones for some great deals right now on Ebay. They arent even a year old cuz the EC was just released last April. Xray is releasing a new buggy in a few weeks and there are lots of folks dumping the ECs and TQs for good prices so they can get the new one. I think they are awesome buggies, infinaltly adjustable and tough as nails. to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#20)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 394

Join Date: Mar 2005

Location: ny

|

03.15.2008, 12:19 AM

my old stadiumm pro had mechanical brakes. saddle packs make it easy.

|

|

|

|

|

|

(#21)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.15.2008, 03:55 AM

Hitec HS5245MG

Torque:61.10 / 76.37 oz.in (4.8v/6v) Speed: .015 / 0.12 sec @ 60 deg. Size:1.27" x 0.66" x 1.21" to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#22)

|

|

|

Guest

Posts: n/a

|

03.15.2008, 06:37 PM

got mine done on my xt8 , but my wife took the kids out of town and has the camera with her so it will be a few days for pics got mine done on my xt8 , but my wife took the kids out of town and has the camera with her so it will be a few days for pics , i used a full sized servo with the frt. and rear brakes, servo fit inbetween the steering servo and pinion, mixed 3rd channel , i used a full sized servo with the frt. and rear brakes, servo fit inbetween the steering servo and pinion, mixed 3rd channelhad to gear 18/48 to use the rear brakes, off to check the speed calc.

|

|

|

|

xt8 with mechanical brakes |

|

|

(#23)

|

|

|

Guest

Posts: n/a

|

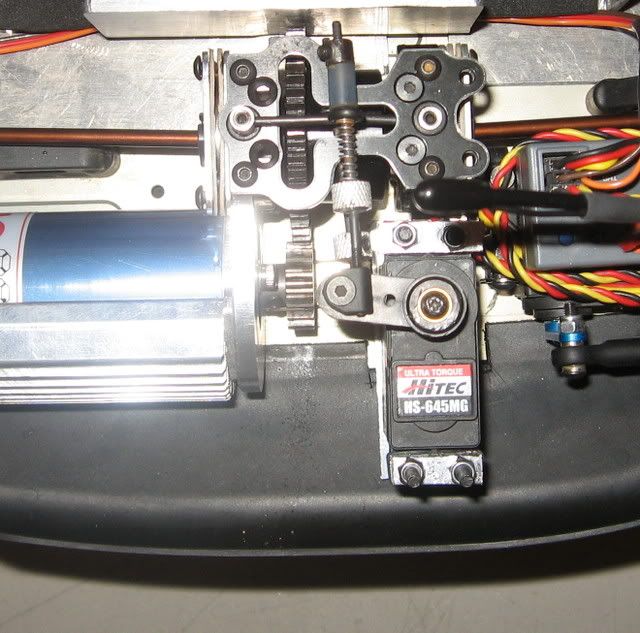

heres some pics, its very solid and works great, took it for a drive today, just dont forget the locktight on the rear screws

my only concearn with this is after 10 minutes of speed runs my temps were 160* motor, and 135* on the esc. w/o fan,(40* outside), but i cant change my gearing , i dont think that a 17 tooth pinion (1 less then now) would work, there is like 1-2mm between the motor can and the rear brake pads any thoughts or comments would be great punch cont. was @ 80% motor timing normal motor start power low **minor cogging on start-up ..... is this caused by the start power or the punch control or timing?? this is not a hyjack, i just thought it would be a great place to discuss these set-ups

|

|

|

|

|

|

(#24)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.16.2008, 05:44 PM

Nice build entjoles

I found the same problem with the gearing when using brake disks. You can only get the motor so close before it rubs the disk. With a standard 36mm can like a Feigao XL or Lehner I can get a 16/46 to work (but its VERY close). The only solution I found was to run a low KV motor and then use the taller gearing to get the speed. If your using a 9xl you may need to go to a 10 or 11 xl to get the right speeds with the gearing that will fit for you. Another thought that I had, but hadn't tried it yet was to get a couple of Mikes motor front plates he makes for the Lehners and Neus and stack them up so it pushes the motor back from the actual motor mount and then you could cut a flat off on the side of the adapter plates to let the disk go in and the disk would actually kinda be between the motor and the motor mouunt plate. That woul let yu get the mtoor in closer with the brake disk. to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#25)

|

|

|

Guest

Posts: n/a

|

03.16.2008, 06:39 PM

the speed calc. says around 40 mph on 4s which is what i run my 9xl on, i will just run it till i thermal or ruin the motor

thanks for the suggestions, do you think that i should consider a 1700kv motor and keep the gearing the same? would the temps be ok? so a 1515 2.5d /s would be a good option? the speed calc. says it would be 39mph i think it felt much better with this braking and i was only running on asphalt |

|

|

|

|

|

(#26)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.16.2008, 09:43 PM

Yea kv wise the 1515/2.5d would be good, but its a bigger diameter so it forces you to use a bigger spur. I would look at going for a 36mm can motor. Feigao, Hacker, Lehner, etc....

to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#27)

|

|

|

Guest

Posts: n/a

|

03.16.2008, 10:14 PM

are the 1512 series the same diameter?

the 3d/s would be an option if it has a smaller diameter, but for some reason i think the neus are the same diameter but are diff. lengths |

|

|

|

|

|

(#28)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.16.2008, 11:31 PM

Yea. All the Neu 15xx motors are the same diameter. The finned cans are even bigger.

I think the Neu smooth cans are about 40mm. That 2 teeth on your pinion you would be giving up with the extra 4mm motor diameter vs a 36mm can motor. to make it... or break it... Silent...But Deadly |

|

|

|

|

|

(#29)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 468

Join Date: Nov 2006

Location: Los Angeles, CA

|

03.17.2008, 02:15 AM

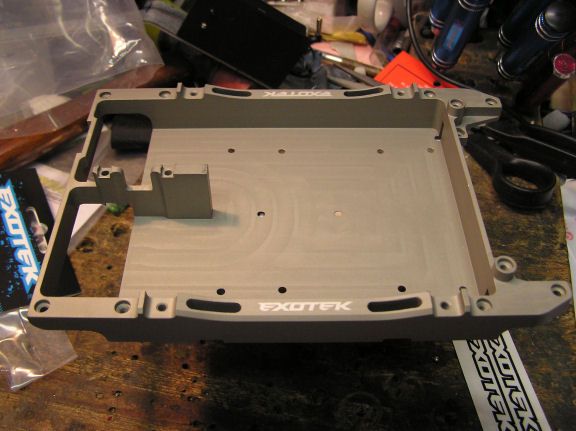

Regarding the pinion clearence, one of the biggest issues using mechanical brakes is that because of the motor can hitting the disc there is a limit on how small you can go on the pinion. I solved this by spacing the motor back a few milimeters so that it clears the disc and therefore I can run very small pinions (10, 11, 12, 13T). Since I am running the Kyosho 46T spur and a hot running Feigao I need to run a 12 or 13T pinion. This also eliminates clogging. On the downside, this setup puts the pinion on the very end of the motor shaft. Because of this I built up the motor mount/chassis to be extra stiff (no flex). So far I have had zero issues with this setup.

This is a 13T pinion.  These pictures show the test fitting and the rough parts (motor mount). |

|

|

|

|

|

(#30)

|

|

|

RC-Monster Mod

Offline

Posts: 4,217

Join Date: Apr 2006

Location: Chicago, IL

|

03.17.2008, 10:25 AM

Looks good shark. That is the solution I was trying to describe a couple posts ago.

Last night I sketched up a spacer plate for the front of a motor that would allow for the brake disk clearance and just sent it to Mike to see if he could machine one up for me. It should allow the use of an almost full range of pinion gears. At least down to 12T by my calculations. It should be able to bolt up to just about any motor using a normal bolt pattern and with any of the RCM style motor moounts allow clearance for brake disks. Like you said though shark, it will put the pinion farther out on the shaft, but I have been running a really long Tekno clutch assembly in one of my buggies which effectivly almost doubles the shaft length where the pinion gear is and havent had any issues so I would think this should be fine too. Heres the sketch of what I'm thinking. to make it... or break it... Silent...But Deadly |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode