|

Custom Outrunner Setup |

|

|

(#1)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

Custom Outrunner Setup -

04.29.2008, 08:06 PM

I thought of this setup for my savage and it looks like it'll work pretty much flawless and it has many positive sides and a few negatives. Plant the outrunner on the savage nitro engine plate with a basic motor mount. Run two center diffs from a buggy/truggy on a custom center chassis mount. Run a dogbone from the outrunner to the 1st diff. The 1st diff powers the 2nd diff which powers the rear/front diffs. Its kinda complicated and some of you may think it is pointless to do all this work for this but I want to try it and see how well it turns out. Keep in mind both center diffs will be locked and will have hardened steel ring gears for added durability. I like this idea because it free's up some space and it puts less stress on the outrunner.

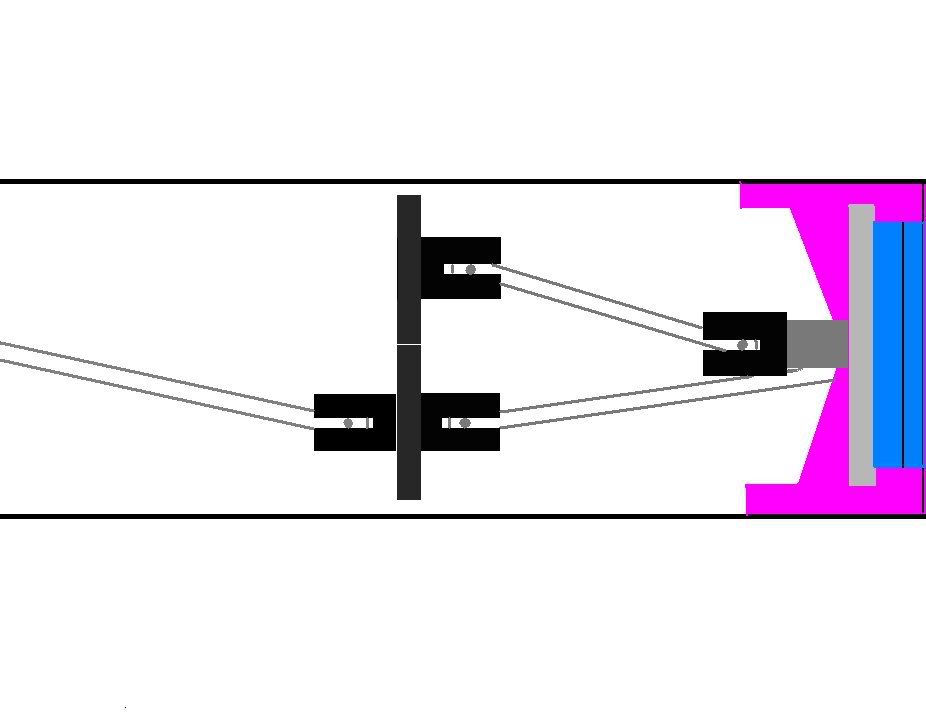

Heres a pic of my idea... (Key- pink= nitro engine mount, blue= outrunner, silver slab infront of outrunner= motor mount, you probably get the rest...)

Lamborghini's= True Engineering Marvel's |

|

|

|

(#2)

|

|

|

RC-Monster Dual Brushless

Offline

Posts: 5,061

Join Date: Oct 2007

Location: Thousand Oaks CA

|

04.29.2008, 08:13 PM

It looks like there will be a lot of stress on the dogbone from the motor to the CD, but I suppose of you use a thick enough dogbone it should work fine.

|

|

|

|

(#3)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

04.29.2008, 08:14 PM

Ya Im looking for super bulky dogbones. I really dont think im gonna have to worry about dogbones snapping, just about them wearing to fast...

Lamborghini's= True Engineering Marvel's |

|

|

|

(#4)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

04.29.2008, 08:31 PM

The front and rear shafts will be turning in opposite directions, unless you put an "idler" gear in between them.

You could run the shaft from the outrunner to the second (bottom) diff and use the first diff (top) to output to the front and rear diffs. Why not just eliminate the outrunners dogbone? You could make an end for the motor shaft that plus right into the diff cup. If you "stacked" the diffs one on the other you would clear the rear shaft and still be on the center line of the chassis and not back so far, plus no funky angles to wear out the diff cups. |

|

|

|

|

|

(#5)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

04.29.2008, 08:38 PM

I like your plan DRKnow. Let me switch up the diagram.

Lamborghini's= True Engineering Marvel's |

|

|

|

(#6)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

04.29.2008, 08:51 PM

Hey td, how does this setup reduce stress on the diffs?

and the standard center spur gear on 1/8th buggies is 45 mm.. so there is 90mm wide or tall.. it seems like it takes up more space then the outrunner.. Looks like a fun project though R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#7)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

04.29.2008, 08:58 PM

I didnt say it will put less stress on the diffs. Just makes me feel safe running the outrunner this way instead of DD.

Lamborghini's= True Engineering Marvel's |

|

|

|

(#8)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

04.29.2008, 09:02 PM

why, i dont see what protection this is adding... and i ment the Outrunner not the diffs srry

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#9)

|

|

|

RC-Monster Aluminum

Offline

Posts: 998

Join Date: Oct 2007

Location: Colorado

|

04.29.2008, 09:02 PM

bb16, I think the idea is to put less stress on the outrunners front bearing. Most outrunners will not have a problem here but why not try it?

I do recall one of the newer rc's having a shaft between the motor and transmission to locate the motor in a better position. Just can't remember what it was. I have found the best learning to be trial and error, experience is good and you'll never come up with something new if you don't try new things. |

|

|

|

|

|

(#10)

|

||

|

Guest

Posts: n/a

|

04.29.2008, 09:42 PM

Quote:

I think you're thinking of Tamiya's truggy the Nitrage. The engine has a dogbone that goes right into a drive cup that is kinda "in" the transmission. http://www.tamiyausa.com/product/ite...oduct-id=43532 |

|

|

|

|

|

|

(#11)

|

|

|

RC-Monster Carbon Fiber

Offline

Posts: 136

Join Date: Jan 2008

Location: Oshkosh WI

|

04.29.2008, 09:59 PM

You will definantly be the first one to do this! If that is why you are doing it then go for t! But imo all of the outrunners you are looking at should handle the strain fine. just mu OPINION. lol

|

|

|

|

(#12)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

04.29.2008, 10:02 PM

im with pb (wow thats a first Lol) its same load on the same exact load on the motor, maybe more cuz of all the rotational mass... and since both difs are locked ther is no stress reduction.. maybe i miniscule amount cuz there is a drive cup on only one side of the motor

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#13)

|

|

|

working on a brushless for my wheelchair.....

Offline

Posts: 4,890

Join Date: Mar 2007

Location: minnesnowta

|

04.29.2008, 10:03 PM

I want to be constructive in my criticism, but I really don't see the point, it's the equivalent of a 46 tooth pinion to center diff setup(assuming 46 tooth cd's) but with added components, extra rotatinal mass and the parasitic power loss of extra parts. Putting a 46 tooth pinion on the outrunner does the same thing, and opens up more room, and costs less, and has less components to fail, and is easier, and makes more sense to me. And why use center diffs if they are locked? That's an awful expensive gear. I'm not trying to bust balls here, but it's like taking the groceries in from the car one item at a time, to my highly sophisticated high school dropout analytical mind anyhoo.

It's "Dr. _paralyzed_" actually. Not like with a PhD, but Doctor like in Dr. Pepper. |

|

|

|

|

|

(#14)

|

|

|

Im not dark, Im over ripened! xD

Offline

Posts: 5,607

Join Date: Sep 2007

Location: Westampton NJ

|

04.29.2008, 10:05 PM

Guess i beat you to it paralyzed :D

R/c Monster Team Driver Jq the car, LST, Sportweks turmoil pro Unconventional Techniques, Superior Results |

|

|

|

(#15)

|

|

|

WARNING: May become violent.

Offline

Posts: 2,426

Join Date: Mar 2007

Location: Wisconsin

|

04.29.2008, 10:05 PM

DrKnow is exactly correct. The reason I want low stress on the outrunner is because I dont want the front bearing to blow and because i dont want anything like the grub screws etc popping out while driving. "That wouldnt be a good situation to be in while doing speed runs".

Lamborghini's= True Engineering Marvel's |

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2025, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode