|

Question about Neu motors |

|

|

(#1)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

Question about Neu motors -

02.15.2009, 08:59 PM

Anyone know if a neu can be rewired from a y termination to a d? I know some of the lehners allowed for this, but not sure about neu motors...

|

|

|

|

|

|

(#2)

|

|

|

Old Skool

Offline

Posts: 7,494

Join Date: Feb 2007

Location: Devon, England

|

02.15.2009, 09:14 PM

Nay saddly. The lehners that couod be rewound (older models or high current models) had 6 external connectors, and Im sure you've seen the two different configurations of the wires coming off of those to achieve delta and wye execution. Alas, the neus onyl have the 3 wires/connectors that are extensions of the windings, no way to re-arrange them.

star  asterix Star is Wye I think, but dont quote me on that... |

|

|

|

|

|

(#3)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 09:26 PM

Quote:

All kinds of winding patterns for outrunners are at my fingertips. If only I had this kind of information on the 4 pole inrunners. I'm sure there are several different ways to wind them. |

|

|

|

|

|

|

(#4)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.15.2009, 10:03 PM

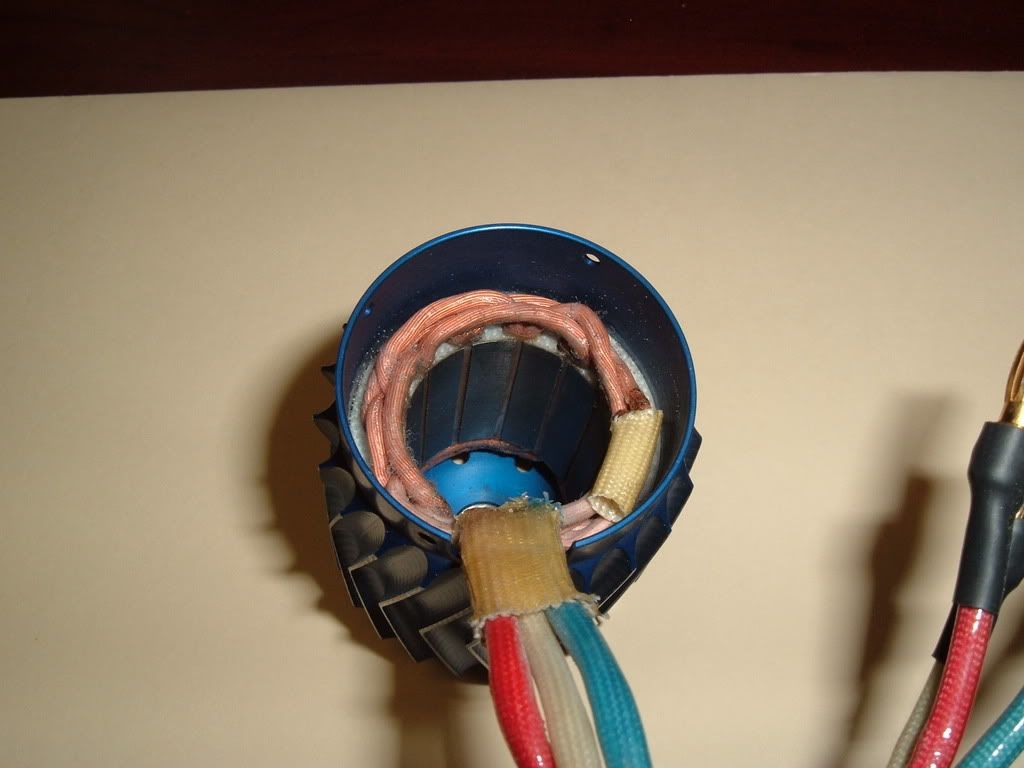

Eyeball this, plett motor internals:

The white wrap on the right side leads me to belive this motor is a star wind, which is delta, IIRC. So a wye wind would have those 3 wires seperated and attached to the main windings that exit the can? I may have the wind types mixed up, but am I anywhere correct with the rewiring? |

|

|

|

|

|

(#5)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 10:09 PM

Quote:

That's a wye termination on a wave wind I believe. Without changing the wind, if you were to sort those out so they match their respective phases, you would increase the kv by 1.73 times. If that is currently 3000kv, I don't think this would be a good idea without changing the wind entirely. A Delta wind is fine in the correct configuration, but I'm not sure how well it would work with only 1 turn. I turned to the Power Croco site which gives MANY different configuration for many pole counts, but they are all outrunner motors. We need to know the configurations of the factory Neu winds. They can be changed in various ways to produce different results. |

|

|

|

|

|

|

(#6)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 10:11 PM

I may be off somewhat on the previous post.

I don't have a good understanding of the wave wind yet. It only uses 1 wire composed of many different strands aka 1 turn. |

|

|

|

|

|

(#7)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 10:15 PM

Quote:

I believe with this configuration, it is magnetizing all three teeth to create one magnetic pole X4. When the ESC shifts to the next phase, it jumps one tooth with the NSNS magnetic polarity. It is a 4 pole armature? correct? |

|

|

|

|

|

|

(#8)

|

|

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.15.2009, 10:16 PM

My main question is can I rewire a neu 2y to a neu 2d...

|

|

|

|

|

|

(#9)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 10:22 PM

This 12 tooth field isn't a 2Y winding. It's wave wound.

Do you have an example of a Neu 2y handy? Sorry for being so difficult, but I believe the 2y will be a different configuration altogether. To answer your question, I'm sure it would be hard. Usually the winding for Delta is continued on both sets out to the main leads. Some manufacturers like Medusa choose the make the leads out of the winding wire itself. (It's why Medusa leads are so stiff) If you were going to simply change from wye to Delta without rewinding the entire thing, when you separate the wye termination point, the leads will be too short. It can be changed, but you have to rewind the whole thing. |

|

|

|

|

|

(#10)

|

|

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 10:48 PM

http://www.rc-monster.com/forum/show...t=15900&page=2

page 2 of this thread shows 2 different Neu motors. They are both wye wound. The one on the left is a 1515, the one on the right is a 1512. Evidently, with the 1515, they were just about out of room inside the can to complete the wind. So they epoxied, compressed and baked the winding to retain that shape. These are both Wye wound. See the white collar covering the termination point? A Delta wind won't have this. |

|

|

|

|

|

(#11)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.15.2009, 11:17 PM

Quote:

|

|

|

|

|

|

|

(#12)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 11:25 PM

Quote:

Once you have the core removed, all the old winding is removed and discarded. If the coating on the laminations is intact, you're lucky. If it isn't, it needs to be recoated. This coating is there to prevent tearing the enamel on the magnet wire as you pull it and do the winding. It pays to eliminate all the sharp edges. Any short phase to phase, or phase to core, and you're not so lucky. Any shorts means starting over. |

|

|

|

|

|

|

(#13)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.15.2009, 11:34 PM

Quote:

|

|

|

|

|

|

|

(#14)

|

||

|

RC-Monster Brushless

Offline

Posts: 2,085

Join Date: Sep 2007

|

02.15.2009, 11:39 PM

Quote:

This really isn't a good spot to make splices. It's so limited on space and the coating on surrounding wires can get melted when doing a solder splice. Not good. I plan on taking that Pletty all the way apart like I described. Carefully unwinding it, while making a diagram of exactly how it's wound. We must do surgery. LOL

|

|

|

|

|

|

|

(#15)

|

||

|

Check out my huge box!

Offline

Posts: 11,935

Join Date: Aug 2007

Location: Slidell, LA

|

02.15.2009, 11:42 PM

Quote:

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

Powered by vBulletin® Version 3.8.11

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Copyright ©2000 - 2026, vBulletin Solutions Inc.

vBulletin Skin developed by: vBStyles.com

Linear Mode

Linear Mode